- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Non-contact measurement system inlineautomaticfor production linesfor the automotive industry

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Applications

- for the automotive industry, for production lines

- Other characteristics

- non-contact

Description

Designed specifically for the inline automotive environment, ‘Inline’ can speed up your quality control processes by:

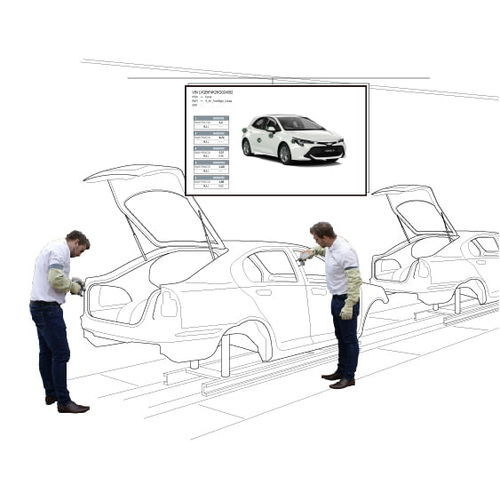

Enabling multiple operators to work from one plan

Presenting the check plan and progress on screen

Automating check plan selection

Outputting data immediately in variety of formats including, QDAS and FLAGS

Identify defects in the production line earlier

Inline integrates multiple GapGun® units with your existing systems, so live data can be transmitted from the factory floor to the metrology lab for immediate analysis.

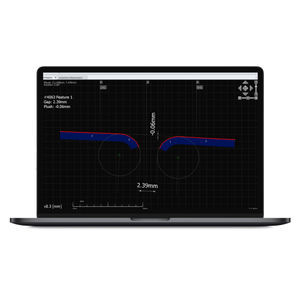

System alerts notify Quality Assurance managers of measurements out of tolerance, whilst large screen measurement visualisation can support the operator in working quickly and efficiently.

Reduce measurement cycle time further, with Inline software

Automatic check plan selection can be activated with Inline, as either a serial number, SOAP message or barcode scanner, removing the manual task of an operator. Measurements can be carried out by more than one operator reducing the time to complete one check plan.

Operators can refer to both the instructional graphic on their GapGun® for a focused understanding of the feature being measured, and the screen for an overview.

Using Inline, measurements will automatically be transmitted to your database, so time is furthermore saved, as operators do not need to do this manual upload.

Catalogs

No catalogs are available for this product.

See all of Third Dimension‘s catalogsRelated Searches

- Measuring device

- Measuring machine

- Portable measuring device

- Automatic measuring machine

- Industrial gauge

- Measuring device with display

- Non-contact measuring machine

- High-precision measuring device

- Geometry measuring device

- USB measuring device

- Measuring system for the automotive industry

- Non-contact measuring device

- Production line measuring machine

- Laser measuring device

- Surface measuring device

- Dimensions measuring device

- Measuring instrument for the automotive industry

- Volume measuring instrument

- Surface roughness gauge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.