- Products

- Catalogs

- News & Trends

- Exhibitions

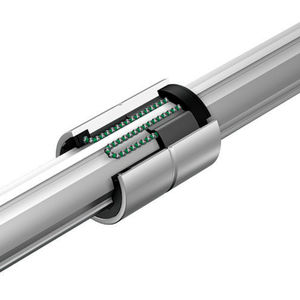

Metal shaft LTR seriesball splinetransmissioncompact

Add to favorites

Compare this product

Characteristics

- Material

- metal

- Configuration

- ball spline

- Product applications

- transmission

- Other characteristics

- compact, machined

- Torque

Max.: 1,040 Nm

(767.0646 ft.lb)Min.: 31.4 Nm

(23.1595 ft.lb)- Diameter

Max.: 134 mm

(5.28 in)Min.: 52 mm

(2.05 in)- Length

Max.: 140 mm

(5.512 in)Min.: 50 mm

(1.969 in)

Description

With the Model LTR rotary ball spline, the spline shaft has three crests on the circumference, and along both sides of each crest, two rows of balls (six rows in total) are arranged to hold the crest so that a reasonable preload is applied.

Angular-contact ball raceways are machined on the outer surface of the spline nut to constitute support bearings, allowing the whole body to be compactly and lightly designed.

The rows of balls are held in a special resin cage so that they stay aligned and recirculate. With this design, balls will not fall even if the spline shaft is removed.

In addition, a dedicated seal for preventing the inflow of foreign material into the support bearings is available.

With the Rotary Ball Spline model LTR, the spline shaft has three crests on the circumference, and along both sides of each crest, two rows of balls (six rows in total) are arranged to hold the crest so that a reasonable preload is applied.

Angular-contact ball raceways are machined on the outer surface of the spline nut to constitute support bearings, allowing the whole body to be compactly and lightly designed.

The rows of balls are held in a special resin retainer so that they smoothly roll and circulate. With this design, balls will not fall even if the spline shaft is removed.

In addition, a dedicated seal for preventing foreign material from entering the support bearings is available.

No Angular Backlash

Two rows of balls facing one another hold a crest, formed on the circumference of the spline nut, at a contact angle of 20° to provide a preload in an angular-contact structure. This eliminates an angular backlash in the rotational direction and increases the rigidity.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.