- Products

- Catalogs

- News & Trends

- Exhibitions

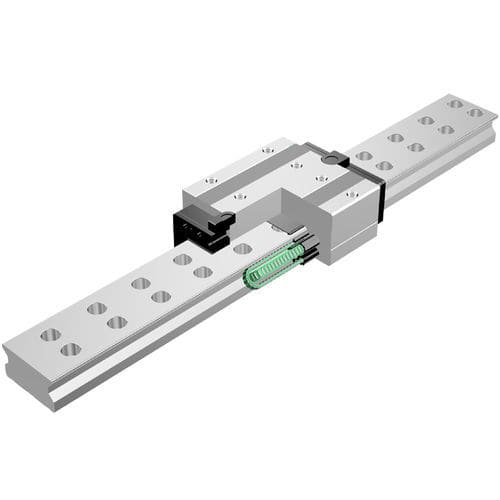

Caged roller linear guide SRW serieswidemaintenance-freehigh-rigidity

Add to favorites

Compare this product

Characteristics

- Technology

- caged roller

- Other characteristics

- wide, high-rigidity, maintenance-free

- Load

Min.: 115 kN

Max.: 1,170 kN

- Size

70 mm, 85 mm, 100 mm, 130 mm, 150 mm

(2.76 in, 3.35 in, 3.94 in, 5.12 in, 5.91 in)

Description

By increasing the width of the roller guide, the mounting strength and mounting stability have been improved.

Based on Caged Roller LM Guide model SRG, this model has a wider rail and two rows of LM rail mounting holes to achieve high mounting strength and mounting stability. SRW is an ultra-high rigidity Roller Guide that uses roller cages to allow low-friction, smooth motion and achieve long-term maintenance-free operation.

Ultra-high Rigidity

Since it has a wide rail and can be secured on the table using two rows of mounting bolts, the mounting strength is significantly increased. In addition, since the crosswise raceway distance (L) is large, model SRW is structurally strong against a moment load (Mc moment) in the rolling direction.Furthermore, model SRW uses rollers that show little elastic deformation as its rolling elements, and the overall length of each roller is 1.5 times greater than the diameter, thus to increase the rigidity.

Smoothness Achieved through Skewing Prevention

The roller cage allows rollers to form an evenly spaced line while circulating, thus preventing the rollers from skewing as the block enters an loaded area. As a result, fluctuation of the rolling resistance is minimized, and stable, smooth motion is achieved.

Long-term Maintenance-free Operation

Use of the roller cage eliminates friction between rollers and enables the lubricant to be retained in grease pockets formed between adjacent rollers. As the rollers circulate, the grease pocket serves to provide the required amount of lubricant to the contact curvature of the spacer and the roller, thus to achieve long-term maintenance-free operation.

Catalogs

No catalogs are available for this product.

See all of THK‘s catalogsRelated Searches

- Linear motion system

- Plain bearing

- Metal plain bearing

- Slewing bearing

- Steel linear guide

- Rod end

- Ball bearing linear motion system

- Slide linear motion system

- Compact linear motion system

- Single-row slewing bearing

- Linear bearing

- Linear ball bearing

- Precision linear motion system

- Track linear motion system

- Roller carriage block

- Metal shaft

- Steel plain bearing

- Block-bearing

- Axis cam follower

- Female rod end

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.