- Products

- Catalogs

- News & Trends

- Exhibitions

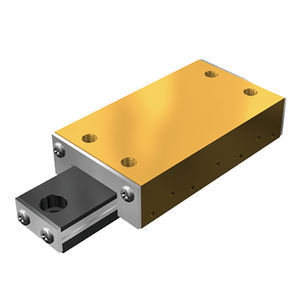

Slide guideway ER seriesminiatureprecisionstainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- slide

- Other characteristics

- stainless steel, precision, miniature

- Rail length

Max.: 56 mm

(2.2 in)Min.: 22 mm

(0.87 in)- Rail width

Max.: 25 mm

(0.98 in)Min.: 13 mm

(0.51 in)

Description

The Model ER is a slide unit using a stainless steel plate that is precision-formed, heat-treated, and then ground.

It has a structure where balls roll between the V-shaped grooves machined on the outer rail and the inner block to allow the system to slide. It is an ultra-thin, lightweight unit in which the balls circulate in a ball cage incorporated in the inner block to perform infinite straight motion.

This model is used in extensive applications such as magnetic disc devices, electronic equipment, semiconductor manufacturing equipment, medical equipment, measuring equipment, plotting machines, and photocopiers.

Model ER is a slide unit using a stainless steel plate that is precision formed, heat-treated and then ground. It has a structure where balls roll between the Vshaped grooves machined on the outer rail and the inner block to allow the system to slide. It is an ultrathin, lightweight unit in which the balls circulate in a ball case incorporated in the inner block to perform infinite straight motion. This model is used in extensive applications such as magnetic disc devices, electronic equipment, semiconductor manufacturing equipment, medical equipment, measuring equipment, plotting machines and photocopiers.

Reduced Design and Assembly Costs

It provides a highly accurate linear guide system with lower design cost and fewer assembly manhours than the conventional miniature ball bearings used in precision machines and other equipment.

Maintains Long-term Stability

It is a ball-circulating type slide unit with an extremely small friction coeffi cient. This slide unit maintains stable performance over a long period of time.

Catalogs

No catalogs are available for this product.

See all of THK‘s catalogsRelated Searches

- Linear motion system

- Plain bearing

- Metal plain bearing

- Slewing bearing

- Steel linear guide

- Rod end

- Ball bearing linear motion system

- Slide linear motion system

- Compact linear motion system

- Single-row slewing bearing

- Linear bearing

- Linear ball bearing

- Precision linear motion system

- Track linear motion system

- Roller carriage block

- Metal shaft

- Steel plain bearing

- Block-bearing

- Axis cam follower

- Female rod end

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.