Gantry coordinate measuring machine CMM RAPID Plus multi-sensorhigh-precision

Add to favorites

Compare this product

Characteristics

- Structure

- gantry

- Probe type

- multi-sensor

- Other characteristics

- high-precision

- X travel

Max.: 800 mm

(31.5 in)Min.: 500 mm

(19.69 in)- Y travel

Max.: 1,500 mm

(59.06 in)Min.: 700 mm

(27.56 in)- Z travel

Max.: 700 mm

(27.56 in)Min.: 500 mm

(19.69 in)

Description

CNC coordinate measuring machine RAPID-Plus

Coordinate measuring machines "Made in Germany" by THOME Präzision

Advantages of the CNC coordinate measuring machine RAPID-Plus

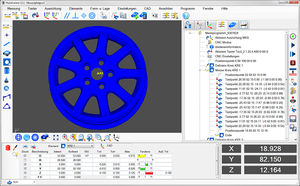

User-friendly measurement software ThomControl

Fast measurement results thanks to simple operation

The ThomControl measurement software is very easy to use and extremely convenient. Extensive graphic support allows even inexperienced operators to measure efficiently and quickly after just a few days. With the teach-in process, measuring programs can be taught in using a joystick. The elements can be clicked directly on a CAD model and automatically measured. The measurement program is written in the background. CNC probing strategies are available for all elements, which are visually displayed and can be configured as required.

The measurement program is created by simply clicking on the CAD elements. The target values are generated automatically and taken over from the CAD data record. This ensures the optimal vector approach to the measuring points. Any number of measuring points can be approached even in difficult zones.

When printing the measurement protocols, the output can be sorted according to various criteria. The operator can also individually determine which element is to be output at which position in the measurement report. The measurement reports can be saved in PDF, WORD and EXCEL format. The clear report editor enables the quick and easy creation of graphical, tabular or combined measurement reports.

Catalogs

CMM RAPID Plus CNC

23 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.