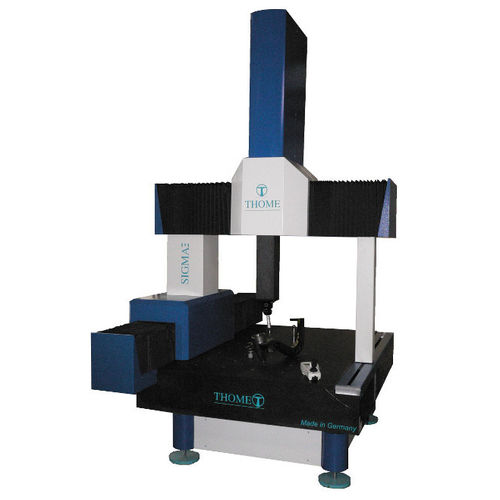

Bridge coordinate measuring machine SIGMA / TETA CNCmulti-sensorhigh-precision

Add to favorites

Compare this product

Characteristics

- Structure

- bridge

- Probe type

- multi-sensor

- Other characteristics

- high-precision

- X travel

Max.: 4,000 mm

(157.48 in)Min.: 1,000 mm

(39.37 in)- Y travel

Max.: 1,200 mm

(47.24 in)Min.: 800 mm

(31.5 in)- Z travel

Max.: 1,000 mm

(39.37 in)Min.: 700 mm

(27.56 in)

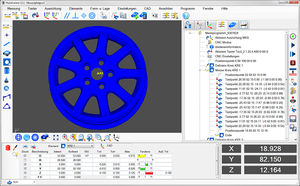

Description

Flexibility of the measuring range in all axis

The new generation of our Coordinate Measuring Machine SIGMA / TETA is characterised by the highest precision, durability and nearly maintenance-free operation.

All our 3D-Coordinate-Measuring-Machines are equipped with optimized air bearing guides in all axis.

Thermal stability and high rigidity is reached by using the highest quality materials such as high precision granite guides or ceramics.

The thermal stability and high precision of the guides guarantee the most accurate measuring results, even without the use of software compensation.

A double passive vibration damping system is integrated in the support frame of the Coordinate Measuring Machines.

Additionally, all our CMMs can be delivered with an active pneumatic vibration damping system. This allows you to absorber even very low frequency vibrations.

All our Coordinate Measuring Machines are equipped with totally covered guides. This helps to protect the guides against dirt, damage and direct thermal influences.

High-dynamic servo-motors and highly rigid, low friction belt drives guarantee optimized positioning behavior. Because of these characters our Coordinate-Measuring-Machines are particularly suitable for scanning!

Our modular component system allows the combination of a lot of axis lengths. We would be pleased to produce your individually measuring machine for you.

Reliability and Precision at a Top Price

Especially the solid covering of the two table guides offers optimal protection against damaging during the loading and unloading of the CMM.

Your Advantages

Catalogs

No catalogs are available for this product.

See all of THOME Präzision‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.