Measurement monitoring device I-CAREprocessautomaticdata acquisition

Add to favorites

Compare this product

Characteristics

- Applications

- measurement, process

- Other characteristics

- automatic, data acquisition

Description

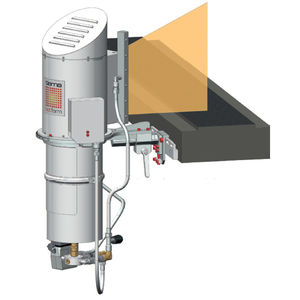

Dedicated to Hot-End monitoring, the I-Care is ready to deliver:

- Relevant information to improve pack-to-melt ratio

- Process trends and stability analysis

- Article position analysis (wrong spacing, stuck or fallen articles)

- Global and specific statistics defining the process

- Detection and rejection of critical defects (Birdswings, stones, freaks etc.)

The innovative I-Care system is a major breakthrough in improving the glass container forming process. This system is automatically synchronized to the IS machine to identify the section and cavity origin.

I-Care takes infrared high quality pictures of each cavity directly after the IS machine.

The images are stored and analyzed to obtain:

- Infrared radiation measurement and graphs

- Immediate alarms if deviation appears

- Bad articles automatic ejections to avoid broken glass parts in the annealing lehr

- Statistics and reporting

Related Searches

- Inspection system

- Measurement monitoring device

- Inspection machine

- Camera inspection system

- Environmental monitoring device

- Industrial control system

- Monitoring control system

- Process monitoring device

- Automatic inspection machine

- Benchtop monitoring system

- Automatic monitoring device

- Process control system

- Compact monitoring device

- Data acquisition monitoring device

- Vision system

- Defect detection inspection system

- Defect inspection machine

- Measurement inspection machine

- Visual inspection machine

- Infrared monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.