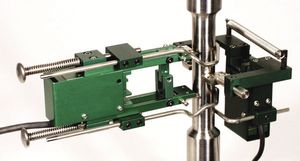

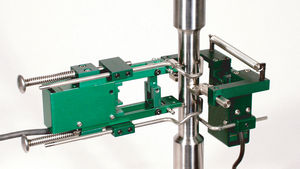

Strain gauge extensometer VectorExtensometer U200high-resolutioncompacttensile

Add to favorites

Compare this product

Characteristics

- Options

- strain gauge, tensile, high-resolution, compact

Description

Single variable length gauge measurement

From 10-150mm gauge length, dependent on elongation % within 200mm FOV

Tinius Olsen introduces Vector a step change in extensometer technology capable of replacing multiple contacting and non-contacting sensors with a single, industry specific instrument.

Integrating adaptive AI capabilities with optical hardware, Vector reduces test throughput times and complexity, automating the process of capturing strain, improving measurement accuracy, data consistency and operator safety.

FEATURES & BENEFITS-

● Non contacting with digital placement of specimen gauge marks supporting an automated process.

● 0.5 μm resolution (1.9685039e-5 inch), ISO 9513 Class 0.2 and ASTM E83 Class B1 capable.

● Various marking options available, material dependent. Dots, rings, lines, speckles, including material surface tracking.

● Output data available in analog and or serial digital formats.

SPECIFICATIONS-

Field of View: Fixed 200H x 75W x 100D[mm] cuboid

Real-Time Data Rate: ≥ 100 Hz, platform dependent. Full system from acquisition to output.

Strain Outputs: Analog Output: ±10V, short-protected, selectable units and range; includes 2.4 m (8 ft) shielded output cable

Digital Output: 16-64 bit serial; includes 1.8 m (6 ft) shielded null modem cable

Resolution: <0.5 μm quasistatic, and cyclic; Typical RMS resolution at typical settings.

Resolution is a function of the marking data rate and filter settings

Extensometer Accuracy Class: ISO 9513 Class 0.2 and ASTM E83 Class B-1 or better typical at ≥10 mm gage

length

Catalogs

No catalogs are available for this product.

See all of Tinius Olsen‘s catalogsRelated Searches

- Test machine

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Benchtop indentation hardness tester

- Compression test machine

- Climatic test chamber

- Digital hardness tester

- Universal test machine

- Flexure testing machine

- Tensile test machine

- Automatic test equipment

- Precision test machine

- Rockwell indentation hardness tester

- Electromechanical test machine

- Brinell indentation hardness tester

- Vickers indentation hardness tester

- Hydraulic test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.