- Packing - Handling - Logistics

- Packing and Packaging

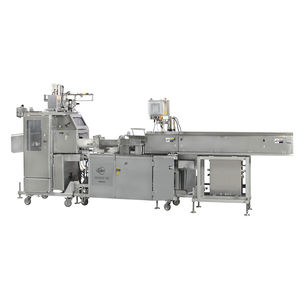

- Automatic packaging machine

- TIPPER TIE TECHNOPACK GmbH

Automatic packing machine TN2002Bfilmhorizontalfor tires

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Type

- film, horizontal

- Applications

- for tires

- Domain

- for the food industry

Description

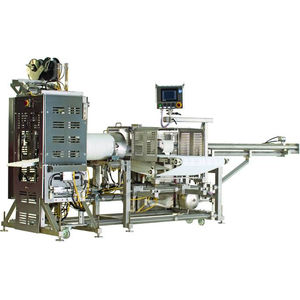

Do you process products that utilize precut and clipped pieces of netting? Then you understand the problems associated with netting waste on a per unit basis. Wouldn't it be exciting if a machine could reduce labor, produce a tight package and only use the specific amount of netting necessary for each product? Stop imagining and start saving with the TIPPER Netter TN2001B. This machine has been specifically created to eliminate labor and netting waste by automating the entire netting and clipping cycle.

Labor can be reduced by up to two workers (depending on your operation) through the machine's automated piston pusher, quick load rucked netting chute and automatic double clipper combination. Additionally, netting waste associated with excess product tails from "one size fits all" precut and clipped netting pieces are no longer an issue.

The TIPPER Netter TN2001B can net and clip most products such as large bone-in hams, small briskets and molded items - just to name a few. It also accepts all types of rucked netting including cotton, elastic, plastic and poly. The TN2001B is designed to meet the AMI sanitation guideline principals. TIPPER TIE engineers always design products with sanitation and wash down processes in mind.

VIDEO

Catalogs

No catalogs are available for this product.

See all of TIPPER TIE TECHNOPACK GmbH‘s catalogsOther TIPPER TIE TECHNOPACK GmbH products

TIPPER TIE Packaging - Netting and Clipping Systems

Related Searches

- Packing machine

- Automatic packing machine

- Bagging machine

- Automatic bagging machine

- Packing machine for the food industry

- Vertical bagging machine

- Film packing machine

- Horizontal bagging machine

- Horizontal packing machine

- Semi-automatic bagging machine

- Vacuum bagging machine

- Packaging system

- Poultry bagging machine

- Tire packing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.