- Food industry

- Meat Processing

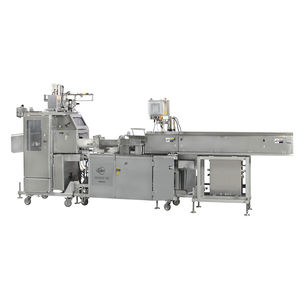

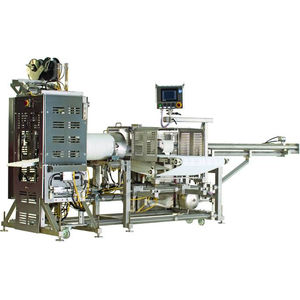

- Net clipping machine

- TIPPER TIE TECHNOPACK GmbH

Net clipper TN4200for foodpneumatic

Add to favorites

Compare this product

Characteristics

- Container type

- for nets

- Applications

- for food

- Operation

- pneumatic

Description

The new TN4200 with servo-powered compression breech draws from the proven technology base of the successful TN4001. It has added dynamic features designed to reduce operating costs, increase productivity, and lower total cost of ownership for packaging hand-placed, whole muscle meats.

The machine has a noticeably longer 812mm (32 inches) breech enabling it to handle larger and longer products like boneless hams, loins, steaks, whole muscle deli slices and more. The unique servo-powered breech presses large products and changes their shapes to fit the casing or netting. Compression creates immediate processing benefits like improved cooking and slicing yields due to more uniform product shape and diameter. Finished packaging inventory mix can also be rationalized because fewer package sizes are needed.

The TN4200 is the first and only whole muscle system with a servo-driven pushing unit. It is fast acting, provides a degree of control and product consistency unachievable with a pneumatic system, and reduces overall maintenance costs due to fewer wear parts. After the meat is compressed in the servo breech the pusher starts. Each of three critical process phases – initial push, main travel, and final push – can be programmed to the needs of the application, their speeds and motions precisely controlled and continuously repeated. With a single operator the TN4200 can package 8 pieces per minute or more and uses the same reliable clipper and voider design as the proven RS series.

VIDEO

Catalogs

TN4000 Family

4 Pages

Rucker

4 Pages

Other TIPPER TIE TECHNOPACK GmbH products

TIPPER TIE Packaging - Netting and Clipping Systems

Related Searches

- John Bean Technologies clipping machine

- John Bean Technologies food clipping machine

- Meat kneader

- John Bean Technologies sausage clipping machine

- John Bean Technologies pneumatic clipping machine

- John Bean Technologies brine injector machine

- John Bean Technologies automatic clipping machine

- Sausage casing clipper

- John Bean Technologies meat brine injector machine

- John Bean Technologies net clipping machine

- John Bean Technologies sack clipping machine

- Industrial meat tenderizer

- Meat tenderizer

- Manual clipper

- John Bean Technologies fish brine injector machine

- Vacuum meat kneader mixer

- Semi-automatic clipper

- Blade meat mixer

- Plastic clip clipper

- Chemical clipper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.