- Industrial machines and equipment

- Mixing and Dosing

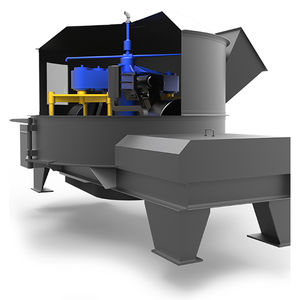

- Planetary mixer

- Titan Machinery LP

Planetary mixer iM Seriesbatchhorizontalautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- planetary

- Batch/continuous

- batch

- Configuration

- horizontal

- Other characteristics

- automatic

- Applications

- construction

Description

TITAN series intensive mixers are the leaders of TITAN MACHINERY’s line of mixing equipment in terms of mixing quality.

Intensive mixers are very powerful units. Their working principle is based on quickly rotating blades. The uniformity of the mixture flow to the high-speed blades is provided by the incident flow, which is formed by the rotating crushing cylinder. The mixture flow is directed by special plows, which clean the pan’s walls as well. In our mixers, the mixture discharge is performed through a central discharging hole with a separate drive.

TITAN Intensive mixer can have a cermet (tungsten carbide) lining*. It provides long-term operation under the harshest conditions when working with highly abrasive raw materials. The pan’s surface is lined using different types of steel or other materials.

We produce intensive mixers in a wide assortment of standard sizes. We have also developed special options of intensive mixers (for mixing hazardous mixtures, etc.) for some exceptional cases.

Intensive mixers provide great mixing quality with excellent homogenization.

Intensive mixing:

Intensive mixing is the process of homogenizing mixtures, which occurs by transferring a large amount of energy with the help of the mixer’s blades that rotate very fast. In this case, the particles that are being mixed break the bonds and conglomerates (lumps) between them. Intensive mixing is such a process that the particles are almost destroyed (milled). Intensive mixers are devices that are somewhere between conventional crushers and mills. In the process of such mixing, even the finest additives are evenly distributed.

Catalogs

No catalogs are available for this product.

See all of Titan Machinery LP‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.