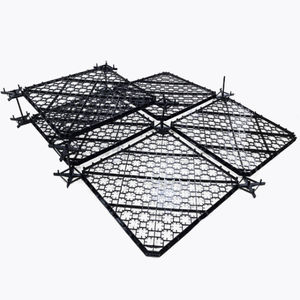

PP structured fill block LTN-9626for cooling towers

Add to favorites

Compare this product

Characteristics

- Material

- PP

- Options

- for cooling towers

Description

The grid fill is the result of an extensive optimization of the lath width, the blockage area ratio and the lath layout;

The water droplets, splashing on a well drained lath, break in a large number of very small droplets, inducing large heat exchange surface. Blockage area ratio and lozenge layout is the optimized compromise between the pressure drop and the probability of large droplets to hit the laths.

The laths height has been selected to transfer the load to the supporting spacers using minimum material quantity.

It may be used as well in Counterflow as in Crossflow cooling towers, mechanical or natural draft.

It is well adapted to any water quality, even without water treatment, when the fouling risk cannot be determined, in particular with seawater

Product Specification

Cooling Tower Film types fills have been popular with the Cooling Tower Industry as a result of their efficiency of not only handling large quantities of water but also the overall tower efficiency. However in the case of heavily contaminated water, film type fills are susceptible to accumulating deposits and often make way for the use of grid type fills for effective water cooling. The forgiving nature of grid fills towards 'dirty' water and imperfect water distribution is offset by the need to have larger towers and thus higher capital costs as well as pumping heads.

Cooling Tower Grid Fills work on the principle of causing the flowing water to fall through a grid of splash bars/grids' causing the water droplets to break up and increasing the contact time between water and air.

Catalogs

No catalogs are available for this product.

See all of TJLATINO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.