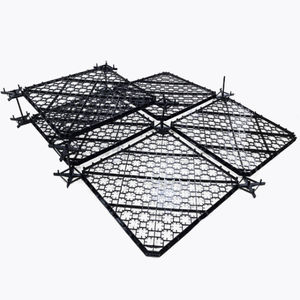

PVC structured fill block LTN-9619polyvinyl chloridefor cooling towers

Add to favorites

Compare this product

Characteristics

- Material

- PVC, polyvinyl chloride

- Options

- for cooling towers

Description

The Cooling Tower PVC Filler is probably the most thermally efficient fill worldwide, has proven its efficiency for more than 30 years.

The sharp horizontal corrugations of cooling tower PVC filler allow even water redistribution on the sheet and water rotation for good contact with air. The offset flute design allows vertical rotation of air with limited pressure drop.

This type of cooling tower fill well adapted to any induced draft or natural draft cooling tower using normal industrial water quality.

SNCS Fill For Counter Flow Cooling Towers

Cooling Tower Pvc Fills consists of thermoformed corrugated sheets made of rigid polyvinyl chloride (PVC), impervious to decay, fungus and biological attack. The cooling tower fill sheets are bonded to form modules which can be dimensioned to fit any application.

Cooling tower PVC fill combines properties related to a media’s ability to allow substances to migrate through it, while maintaining thermal efficiency— this then allows for the use of cooling tower film fill where fouling risks occur.

Each module consists of vertically channeled flat and corrugated surfaces, which essentially avoids contact between the cooling tower fill sheets, thus eliminating water concentration. The horizontal corrugations and their location within the sheet promote optimum mixing of air and water. The flutes in this cooling tower fill are vertically and aerodynamically shaped resulting in a reduction of pressure drop.

VIDEO

Catalogs

No catalogs are available for this product.

See all of TJLATINO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.