- Environment - Health - Safety

- Air Treatment and Noise Management

- Cartridge dust collector

- Tongbao Surface Processing Equipment

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

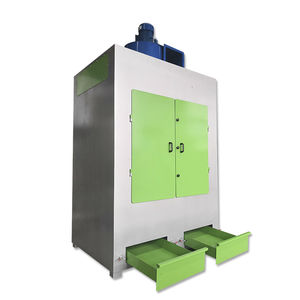

Cartridge dust collector TB-CDC1200-4pulse-jet backflowfor the plastics industryfor welding fumes

Add to favorites

Compare this product

Characteristics

- Technology

- cartridge

- Backflushing

- pulse-jet backflow

- Other characteristics

- for the plastics industry, for welding fumes, automatic

- Output

3,000 m³/h

(105,944.0002 ft³/h)

Description

Pulse filter cartridge dust collector TB-CDC1200-4

1. Integrated structure on the top of the fan: the fan system and the filter system are placed in the same box, and the dust collection system is external, the height of the whole machine is reduced, and the floor space is small.

2. Pulse back-blowing: Adopting filter cartridge cleaning technology, automatic pulse back-blowing ash cleaning, and combined with specially developed spiral injection technology, the cleaning area covers the entire surface of the filter cartridge, and there is no cleaning blind spot.

3. High-precision filtration: The main filter is a polyester fiber substrate imported from Japan, and is treated with PTFE coating. The filtration efficiency of dust particles above 0.3um is more than 99%. At the same time, it can also be equipped with oil-proof, waterproof, anti-static, Flame retardant and higher filtering precision materials.

4. Perfect electrical protection: We are very concerned about motor protection. Thermal overload, phase loss, reverse phase, and phase sequence protection are complete. Most electrical components use Schneider brand. In addition, a remote control port can be added to facilitate linkage control of the host.

5. External large-scale dust collection box: a large-volume dust collection box is installed under the machine. The external structure can reduce the height of the whole machine. The standard configuration has an air-top structure. When unloading, you only need to flip the pneumatic switch at the outrigger. You can put down the dust bucket for easy and quick cleaning.

Catalogs

No catalogs are available for this product.

See all of Tongbao Surface Processing Equipment‘s catalogsOther Tongbao Surface Processing Equipment products

Environmental protection equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.