- Machine-tools

- Machining Center

- Ceramic machining

- Top Seiko Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Silicon carbide machining automotiveindustrialfor aeronautics

Add to favorites

Compare this product

Characteristics

- Treated material

- silicon carbide

- Applications

- automotive, industrial, for aeronautics, medical, for the aerospace industry, for electronics, for robotics, optical, for the nuclear industry

- Production method

- medium series, small series, prototyping, large series

- Product applications

- shaft, spacer, screw, bushings

- Other characteristics

- CNC, precision, 5-axis, 3-axis

- Certifications

- ISO 9001, ISO 13485

Description

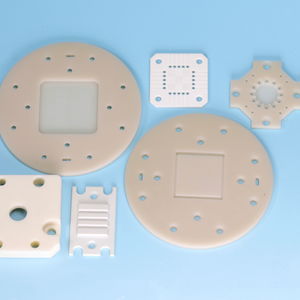

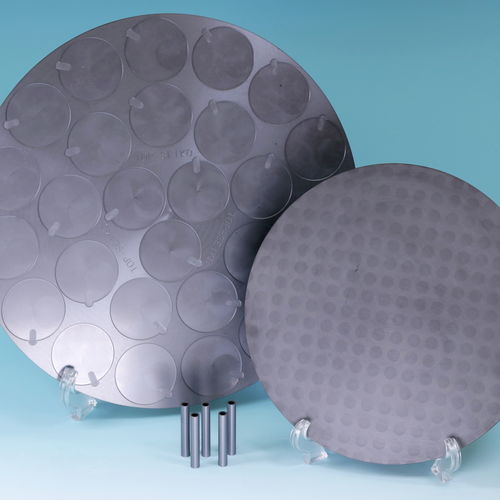

Silicon Carbide has very good mechanical properties and maintains its strength even at extremely high temperatures. It also has excellent resistance to acids, alkalis, and molten salts up to 800°C. These exceptional properties make SiC suitable in applications requiring great resistance to wear, thermal shock, and corrosion.

Top Seiko has extensive experience in precision machining of both Silicon Carbide and Silicon – Silicon Carbide metal matrix composites (Si-SiC MMCs). Similar to Silicon Carbide, MMCs are excellent materials to use when high thermal conductivity and wear resistance are required.

Key Properties

■High hardness

■Wear Resistance

Due to its high hardness, SiC is extremely resistant to scratches and abrasions.

■High Thermal Stability

■High-temperature strength

■Low thermal expansion

■High thermal conductivity

■High thermal shock resistance

SiC can maintain its strength to very high temperatures. It is extremely resistant to thermal shock due to its excellent combination of high thermal conductivity, low thermal expansion, and high strength, and can withstand rapid heating and cooling.

■Chemical resistance

SiC is highly resistant to acids, alkali, and reactive gases.

Applications

■Parts requiring a high level of scratch resistance such as wafer carriers and wafer tray supports

■Turbine components

■Blast nozzles

■Mechanical Seals & Bearings

■Parts requiring high stability and shape retention at high temperatures

■Heat transfer components used at high temperatures such as heaters, heat sinks, and heat exchangers

■Parts used in chemical environments

■Parts subject to deposit removal with acids or alkali

Catalogs

No catalogs are available for this product.

See all of Top Seiko Co., Ltd‘s catalogsRelated Searches

- Machining service

- Milling machining

- Metal milling machining

- CNC milling machining

- ISO machining

- ISO 9001 milling machining

- Precision milling machining

- Turning machining

- Automotive milling machining

- Industrial milling machining

- Small series milling machining

- Medium series milling machining

- Precision turning machining

- Medical milling machining

- Prototyping milling machining

- 5-axis milling machining

- 3-axis milling machining

- Large series milling machining

- Machining for the aerospace industry

- Aeronautic milling machining

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.