- Hydraulics - Pneumatics

- Pump

- Diaphragm vacuum pump

- TOPSFLO INDUSTRY AND TECHNOLOGY CO., LIMITED

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

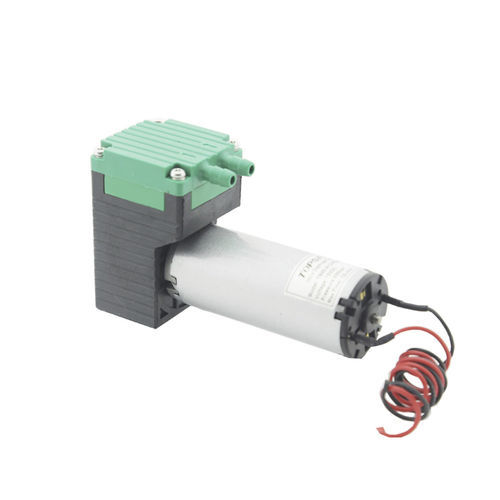

Micro vacuum pump TM40A-A seriesdiaphragmoil-free12 Vdc

Add to favorites

Compare this product

Characteristics

- Technology

- diaphragm

- Lubrication

- oil-free

- Supply voltage

- 24 Vdc, 12 Vdc

- Applications

- for gas, for food, for packaging, for medical devices, air sampling

- Other characteristics

- compact, miniature, micro, brushless DC

- Ultimate vacuum

75,000 Pa

(10.88 psi)- Flow rate

9 l/min, 10 l/min, 13 l/min

(2.38 us gal/min, 2.64 us gal/min, 3.43 us gal/min)- Operating temperature

Min.: 41 °F

(5 °C)Max.: 158 °F

(70 °C)- Length

120 mm

(5 in)- Width

40 mm

(1.57 in)- Height

65 mm

(2.56 in)- Noise level

45 dB

- Weight

350 g

(12.35 oz)

Description

TOPSFLO micro diaphragm pumps and compressors are based on a simple principal,the circular power from the motor is converted into oscillating movement by aneccentric, which moves up and down its central point, this motion is then transferredto a diaphragm by means of a connecting rod, an elastic diaphragm, which inconjunction with an inlet and outlet valve creates a pumping action.

TM 40 pumps can be mounted in any position and can deliver up to 10 l/min, 12L/min (dual head) depending on the model and will operate against pressures of up to 230Kpa.

Features

Highest Performance/Size Ratio

Innovative and efficient engineering designs enable the TM 40 Series to push the performance envelope in a lightweight, compact size.

Performs Quieter

Optimized head, chamber, and flow path reduce noise without compromising performance.

Lasts Reliably Longer

Using the advanced diaphragm elastomer and superior brushless motor design sets the highest benchmark for service-free operation that exceeds 15,000 hours.

Uncontaminated flow

no contamination of the media due to oil-free operation

Little vibration

Because of leading edge technologies, top quality bearing, superior brushless motor

High level of gas tightness

thanks to stress-optimised structured diaphragm, newly-designed valves and sealing systems, precise placement of the pump head

Extreme chemical resistance

The use of chemically resistant materials optional such as PTFE FKM or other ,material combinations for the parts which allows the corrosive gas to be pumped.

Optimal solution for your application

A wide standard range of materials, motors , voltages configurates multiple components system selected

VIDEO

Catalogs

No catalogs are available for this product.

See all of TOPSFLO INDUSTRY AND TECHNOLOGY CO., LIMITED‘s catalogsOther TOPSFLO INDUSTRY AND TECHNOLOGY CO., LIMITED products

Mini Diaphragm Pumps Compressors

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Vacuum generator

- Lubricant pump

- Transfer pump

- Chemistry pump

- Vacuum pump

- Submersible pump

- Suction pump

- Compact pump

- Lubricating oil pump

- Diaphragm pump

- Single-stage vacuum pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.