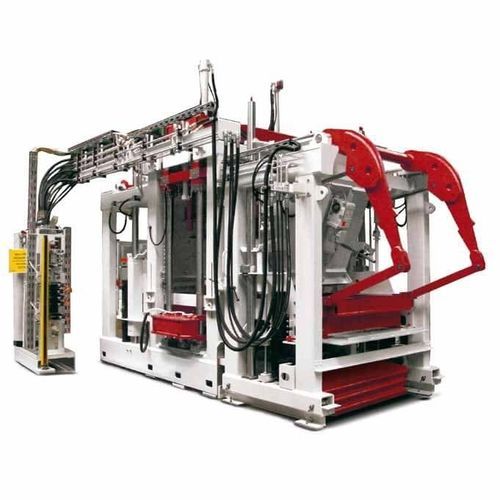

The RH 1400 optimizes cost-efficiency with performance for an Intelligent Investment in the production of high quality concrete products. Complete with its own handling system, it is now possible for customers to grow or expand their market through the advantages of a big board plant at a manageable investment level.

Technical data

production board(mm) - 1.400 x 1.100

production area (mm) - 1.300 x 1.050

min. product height (mm) - 25

max. product height (mm) - 400

dead weight approx. (kg) - 22.500

paver 10x20x6 without face mix -

cycle time - 13

m² in 8h - 2.033

qty stones/form - 54

paver 10x20x6 with face mix

cycle time(s) - 17

m² in 8h - 1.555

qty stones/form - 54

hollow block 20x40x20cm - cycle time(s) - 16

quantity in 8h - 18.360

qty stones/form - 12

Features

Pallet depth maximum (mm) - 1100

Pallet width maximum (mm) - 1400

Minimum manufacturing height (mm) - 25

Maximum manufacturing height (mm) - 400

Mechatronic, frequency control - Standard

Tamper head block height stops 4 pcs. - Option

Tamper head clamping, screwed - Standard

Tamper head clamping, pneumatic - Option

Tamper head cross cleaner, straight - Option

Mold clamping, pneumatic - Standard

Hydraulic function for mold flaps - Option

Mold change, manual - Standard

Mold change crane - Option

Coarse mix Colormix drawer - Option

Coarse mix silo, silo lining PA/Hardox - Option

Coarse mix filler box with agitator cylinder drive - Standard