- Products

- Catalogs

- News & Trends

- Exhibitions

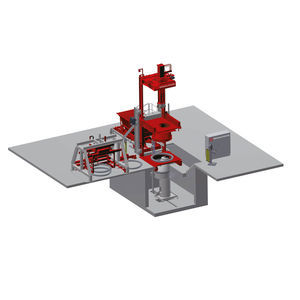

Drainage pipe production line BLIZZARDfor boxesfor concrete manholesautomatic

Add to favorites

Compare this product

Characteristics

- Finished product

- for boxes, for concrete manholes, for drainage pipes

- Other characteristics

- automatic

Description

The stationary automatic BLIZZARD production equipment is designed around a 180º rotating tilt table station for the manufacturing of a wide range of products. The rotating process allows the production of products that previously were restricted to methods involving wet cast moulds and vibration tables. These items can now be manufactured by the use of full automation to achieve greater output and profitability.

PRODUCT CAPABILITIES

-Cable Channels and Distribution boxes

-Drainage Channels

-Steps, Chimneys and other Building Products

-Landscape Elements (Paving Slabs, Columns and Wall Caps etc)

-Retaining Walls

-Manhole Base Units

-Median Barriers and other Road / Rail

-Products

The BLIZZARD is very well suited for the production of

-Products for sewerage

-Products for drainage

-Products for power supply ducts and telecommunication

-Other concrete products

The BLIZZARD technology allows improvement to production efficiency and the enhanced quality of numerous products to meet market demand. The developed vibration technology is precisely controlled allowing all freshly made product to be directly demoulded onto steel pallets for conveyor transfer to curing racks. The average time for a mould cassette change is 10 to 15 minutes this rapid exchange from one mould to another assists in advancing manufacturing flexibility creating client satisfaction. The whole plant can be operated by a single operator

Capacity data

Product dimensions max. Ø - (L x B x H) 1.700 - 1.700 -1.500 mm

Heights max.. - 25 – 1.500 mm

Product weight max. up to - bis 5.000 kg

Cycle times - 1,5 – 5,5 min

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.