- Products

- Catalogs

- News & Trends

- Exhibitions

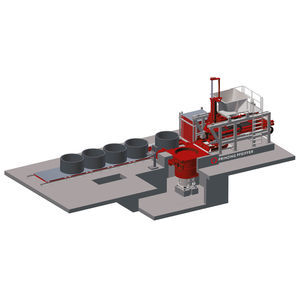

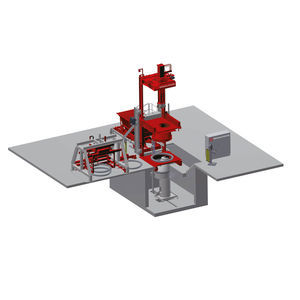

Fresh concrete production plant PRIMUSSfor grainmanhole

Add to favorites

Compare this product

Characteristics

- Product applications

- fresh concrete, for grain, manhole

Description

The benchmark PRIMUSS innovation integrates the highest level of automation and control technology in the design and manufacture of monolithic manhole bases with bespoke mixed inlet and outlet entries and benching. In using proven robotic programming the varying location, diameter and angular dimensions of different pipe inlets permit precise milling by PRIMUSS immediately after product demoulding.

PRODUCT CAPABILITIES

-The efficient PRIMUSS effectively reduces mould and labour expense associated with mould assembly and

-demoulding thus eliminating costs and waste connected with polystyrene formers and plastic liners.

-PRIMUSS lowers tooling and energy costs through the milling of fresh concrete.

-All monolithic manhole bases produced by PRIMUSS are milled from high compacted fine grain concrete.

-Dimensionally precise bases are formed due to partial curing in the mould.

-The base units are manufactured using concrete with high

-strength and low W/C ratio.

-All PRIMUSS channels (benching) are designed for optimum flow.

-The operating software produces a quick setup for complex inlet/outlet design improving manufacturing flexibility from information given by the site engineer.

-PRIMUSS manhole bases set the benchmark standard for best practices in terms of quality, efficiency and roduction output.

Capacity data

Product dimensions max. Ø - 600-1.500 mm

Lengths max. - 250-1.500 mm

Product weight max. - 5.000 kg

Cycle times - 5-25 min

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.