- Products

- Catalogs

- News & Trends

- Exhibitions

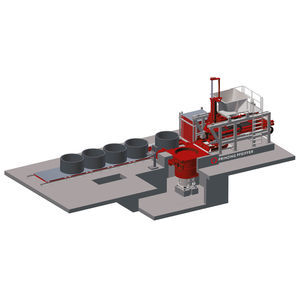

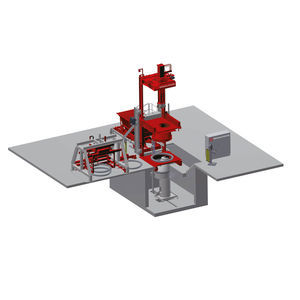

Concrete production plant TORNADOfor pipesmanhole

Add to favorites

Compare this product

Characteristics

- Product applications

- for concrete, for pipes, manhole

Description

The TORNADO machine is established with a solid reputation as a proven and reliable production system for concrete manholes, pipes and similar products such as street gullies. It offers efficient cycle and product change times for these various product types. The TORNADO operating arrangement comprises of four modular components creating a wide range of product flexibility.

PRODUCT CAPABILITIES

-Our patented GEBA process ensures the exact length precision of products.

-Precise forming of concrete pipe and manhole spigots can be achieved through our SYSTEM-OPTIMA method.

-The TORNADO utilizes a pit installed vibrator unit which reduces noise levels.

-The setup is accessible from three sides allowing optional handling systems to accommodate various product types

-The highly effective central vibrator technology assures excellent product quality and together with tamper

-vibration providing exact concrete pipe spigots.

-The hydraulic mould clamping of outer case and inner core in conjunction with the automatic height adjustment

-provide efficient versatility at mould changeover.

-The TORNADO machine can be dedicated either to one type of product or across a scope of products.

Capacity data

Product dimensions max. Ø - 150 – 2.500 mm

Lengths max. . - 250 – 1.500 mm

Product weight max. - 50 – 6.000 kg

Cycle times - 2 – 4,5 min

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.