- Products

- Catalogs

- News & Trends

- Exhibitions

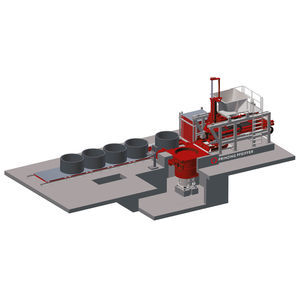

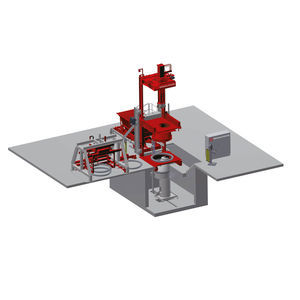

Concrete product production line ZELUSautomatic

Add to favorites

Compare this product

Characteristics

- Finished product

- for concrete products

- Other characteristics

- automatic

Description

The production system ZELUS is fully automated having a high degree of efficiency allowing a closed cycle carousel for a wide range of precast and wet cast products. A crane robot manages the automated handling of up to 130 battery style moulds to racking in an 8 hour working period, then subsequently acting as a demoulding tool. This circular system delivers high quality and a greater output of a range of products previously limited to inefficient static moulds.

PRODUCT CAPABILITIES

-ZELUS has the capability and capacity to produce a wide range of oblique product shapes up to 1 m high x 3 m width x 6 m length with a weight reaching to 5000 kg.

-This highly efficient line has an exact dosing system for the precise filling of individual moulds mounted within

-carrier frames which act as transport pallets to convey newly made product to a curing rack.

-An alternative SCC (self compacting concrete) dosing method can also be implemented.

-A filling depth tolerance of +/- 1 mm is maintained on the finished product.

Capacity data

Product dimensions max. - 6.000 x 3.000 x 1.200 mm

Lengths max. - 6.000 mm

Product weight max. - 1 - 5.000 kg

Cycle times - 3 - 5 min

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.