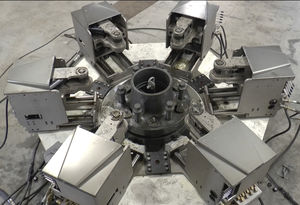

Battery-powered torque multiplier EvoTorque®2 series

Add to favorites

Compare this product

Characteristics

- Type

- battery-powered

- Torque

Min.: 200 Nm

(147.5 ft.lb)Max.: 7,000 Nm

(5,162.9 ft.lb)

Description

This is a powerful tool, perfect for a variety of uses and projects. Our tools are factory calibrated to ±3% of reading and have a unique ‘intelligent joint sensing’ technology that continuously measures the joint during tightening and, when necessary, employs dynamic braking to avoid torque overshoot due to motor inertia.

The EvoTorque®2 can apply torque accurately over a wide range of joint rates from hard (high torque rate) through to soft (low torque rate). All EvoTorque® 2 tools are highly tolerant of supply voltage and frequency variation. When the tool runs, it will run accurately, but if the supply voltage is outside of tolerance, it will be prevented from starting as a safety feature.

The EvoTorque®2 has the ability to memorize multiple targets, work IDs, user IDs and readings. The tool has three modes of operation:

Torque

Torque and Angle

Torque Audit

The unique Audit Mode is a sophisticated feature for testing pre-tightened bolts with minimal impact on the original fastening torque and can provide quality control data for monitoring joint performance over time.

Catalogs

MULTIPLIERAIR TOOLS

12 Pages

Related Searches

- Torque wrench

- High-precision torque wrench

- Adjustable torque wrench

- Hydraulic torque wrench

- Torque wrench for heavy-duty applications

- 3/4" torque wrench

- Torque multiplier

- Nut torque wrench

- Adjustable torque wrench

- Electric torque multiplier

- Torque wrench with hexagonal head

- Pneumatic torque multiplier

- Battery-powered torque multiplier

- Interchangeable head torque wrench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.