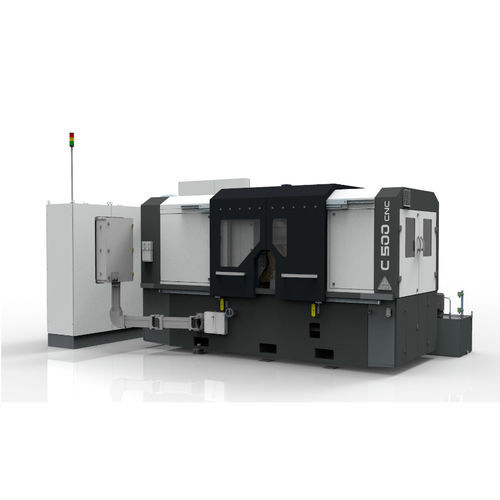

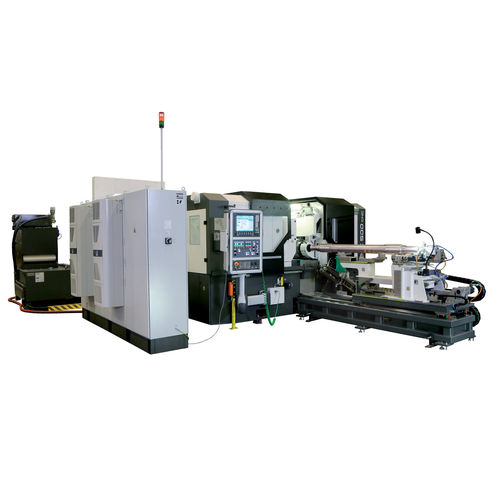

The numerically controlled centreless grinding machines C 500 CNC are designed for precise and powerful grinding of external cylindrical

surfaces in serial and mass production with the possibility of grooving (shaped) or through-hole grinding. With

their fixed fence stand and movable grinding headstock and feed headstock, they are particularly suitable for longer or larger workpieces. The grinders have a grinding and regulating wheel spindle mounted on both sides with a constant cutting speed and are characterized by high rigidity in the tool part. They have a position measuring system in all controlled axes, precise diagnostics of the current situation, including immediate localization of a possible machine failure, remote diagnostics. They allow for very fast and precise adjustment of the grinding machine to a different type and size of the workpiece. They are fully hooded and occupy a minimal built-up area. Thanks to their operational flexibility, they make it possible to solve even the most demanding tasks, placing extraordinary demands on accuracy, performance and flexibility of production.

CE machine design, SIEMENS Sinumerik ONE control system, MCP2200c operator panel with 22″ IPC477E monitor, controlled axes X1, X2, U1, U2, W1, W2, A, B, C1, C2 and C3, remote diagnostics, full fairing with manual door opening.