- Products

- TOSS GmbH & Co. KG

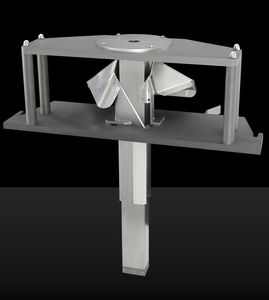

Round forming shoulder

Add to favorites

Compare this product

Characteristics

- Form

- round

Description

Matching characteristics of film and forming shoulder are essential for a fluently and damage-free transformation of film to tube.

Besides thickness and slide characteristics, elasticity of the film will have to be taken into special account during design resp. modelling process of a forming shoulder.

Film qualities with restricted elasticity

· Aluminum-laminated film

· laminated films with Polyester, Polypropylene, paper

Film qualities with high elasticity

· Polyethylene-mono films

· co-extruded multilayer films

Films with restricted elasticity require a forming edge of mathematical precision, higher elastic film qualities require less precise forms for their faultless processing.

A milled forming shoulder tube will result in optimum transforming geometry. This design is universally applicable and meets even the most demanding requirements.

Catalogs

No catalogs are available for this product.

See all of TOSS GmbH & Co. KG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.