- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

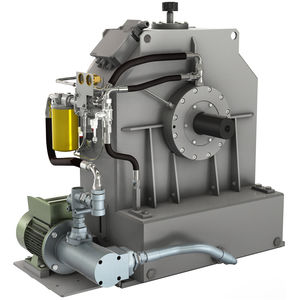

Hydrodynamic coupling 17 KPTB-HSfor pumpfor compressorscentrifugal

Add to favorites

Compare this product

Characteristics

- Type

- hydrodynamic

- Product applications

- for pump, for compressors

- Construction

- centrifugal

- Performance

- high-speed

- Installation system

- shaft sleeve

- Rotational speed

3,600 rpm

(22,619.47 rad.min-1)

Description

HYDRAULIC COUPLING FOR ELECTRIC ENGINES – STARTER

To meet the energy savings and reliability demands modern industry requires, Transfluid has developed two new variable, high-speed hydraulic couplings: the KSL-HS and the KPTB-HS. Capable of input speeds of 3600RPM the HS family of couplings has already found demands in the power, steel, paper, cement, chemical and petrochemical industries. The high-speed products are finding applications in boiler feed pumps, fans, blowers, pumps, compressors.

The features of KSL-HS and KPTB-HS turbo couplings combine a simple design with the high efficiency of a hydraulic coupling to provide an optimal solution for centrifugal machine design.

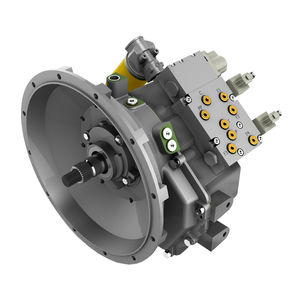

Variable fill fluid couplings: how the control flow system works

TRANSFLUID’s high-speed hydraulic couplings include a control flow system which:

is self-adjusting, since the draining of oil from the calibrated orifices depends on the rotation speed of the outer impeller which is directly connected to the driven machine. This allows the coupling to stabilize its speed in the presence of load variations without the need for corrective actions and “loop” control

eliminates the stationary element (the scoop) and hydrodynamic resistance in the working circuit

operates in forward and reverse

has all key accessories mounted externally, allowing for simple and inexpensive maintenance.

Catalogs

No catalogs are available for this product.

See all of Transfluid‘s catalogsRelated Searches

- Flexible shaft coupling

- Shafts coupling

- Friction brake

- Flange shaft coupling

- Torque shaft coupling

- Spring brake

- Disc brake

- Transmission shaft coupling

- Friction clutch

- Sleeve shaft coupling

- Compact shaft coupling

- Engine shaft coupling

- Hydraulic brake

- Safety brake

- Pump shaft coupling

- Industrial shaft coupling

- Drive system

- Disc clutch

- Machines coupling

- ATEX coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.