- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

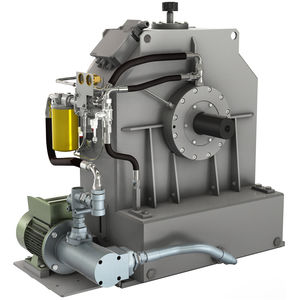

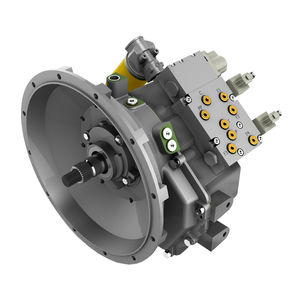

Hydrodynamic coupling KSLpumpfor diesel enginesmachines

Add to favorites

Compare this product

Characteristics

- Type

- hydrodynamic

- Product applications

- pump, for diesel engines, machines, fan, for conveyor, for compressors, for marine applications, for the cement industry, industrial, for heavy loads

- Performance

- high-speed, heavy-duty

- Other characteristics

- torque, variable-speed

- Torque

Min.: 0 Nm

(0 ft.lb)Max.: 80,000 Nm

(59,004.9719 ft.lb)- Rotational speed

Min.: 600 rpm

(3,769.91 rad.min-1)Max.: 3,600 rpm

(22,619.47 rad.min-1)

Description

HYDRAULIC COUPLING FOR ELECTRIC ENGINES – SPEED VARIATOR – STARTER

Transfluid has designed their KSL series variable fill fluid coupling to overcome problems experienced at “start-up” and “speed variation” operation for medium and high power machines driven by electric motors and internal combustion engines.

HYDRAULIC COUPLING: WORKING OPERATION

Extremely efficient performance is achieved operating the fluid coupling KSL’s very simple and effective principle. Oil, which is the power medium, is pumped from a sump to the hydrodynamic coupling circuit, where it is finally “drained off” through a series of orifice plugs, back into the sump.

The “START-UP” principle:

By controlling the coupling’s feed pump oil flow to the working circuit by a small A.C. frequency converter, changes occur inside the coupling working circuit that alter the coupling slip characteristics, which softens the “start-up” dramatically.

The “VARIABLE SPEED” principle:

The same principle used to control the start-up permits the KSL to operate as a variable speed drive, varying the speed between input and output.

Its “TORQUE LIMITING” function:

Another KSL feature is its ability to limit the torque transmitted, slipping for a time and then dumping its circuit oil, disconnecting the driven machinery. The quick disconnection is possible by the installation of a quick release valve.

The key “KSL” features are:

soft start

variable speed

torque limiting

Catalogs

Related Searches

- Flexible shaft coupling

- Shafts coupling

- Friction brake

- Flange shaft coupling

- Torque shaft coupling

- Spring brake

- Disc brake

- Transmission shaft coupling

- Friction clutch

- Sleeve shaft coupling

- Compact shaft coupling

- Engine shaft coupling

- Hydraulic brake

- Safety brake

- Pump shaft coupling

- Industrial shaft coupling

- Drive system

- Disc clutch

- Machines coupling

- ATEX coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.