- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

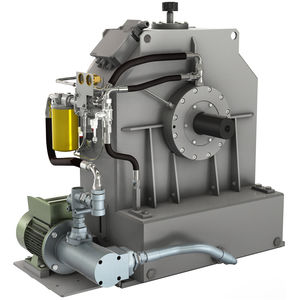

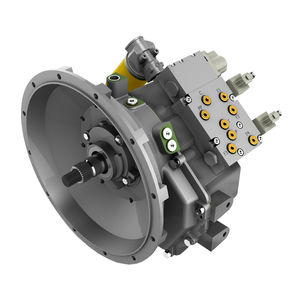

Hydrodynamic coupling SKFfor shaftsfor pumpflywheel

Add to favorites

Compare this product

Characteristics

- Type

- hydrodynamic

- Product applications

- for shafts, for pump

- Construction

- flywheel

- Installation system

- flange

- Torque

Max.: 1,200 Nm

(885.0746 ft.lb)Min.: 0 Nm

(0 ft.lb)

Description

HYDRAULIC COUPLING FOR DIESEL ENGINES – STARTER

The SKF series of Constant Fill Fluid Couplings is used on all industrial equipment types driven by internal combustion engines up to 180 kW requiring a tight flywheel mounting. By transmitting power through a fluid, they improve overall performance and protect both driving and driven machines.

BENEFITS OF SKF CONSTANT FILL FLUID COUPLINGS

When you drive through Transfluid Hydraulic Coupling you profit from these Basic Benefits.

Frees engine during heavy starts

During heavy starts and sudden running load increases, engine lugging is prevented. The Fluid Coupling simply “slip” while it smoothly picks up the load.

Provides smoothly drive

The mechanical connection is eliminated; power and torque are transmitted entirely through fluid mass and velocity. The result is a smooth, sustained flow of energy minus the shocks and strains which, with mechanical drives, cut equipment life.

Prevents transmission of shock loads

Fluid Couplings protect both driving and driven equipment by smoothing out shock loads and preventing them from striking solid resistance.

Assures damping effects

Torsional vibrations from the engine are drastically dampened by the Fluid Coupling, increasing the entire transmission’s life.

Transmits full input torque

The patented Transfluid Circuit design delivers output torque always equal to input torque. The engine can turn at its max torque-rpm, even when driven is at stall.

Radial load capability.

The SKF series includes the SKFE line which allows the installation of a pulley on output shaft.

Catalogs

Related Searches

- Flexible shaft coupling

- Shafts coupling

- Friction brake

- Flange shaft coupling

- Torque shaft coupling

- Spring brake

- Disc brake

- Transmission shaft coupling

- Friction clutch

- Sleeve shaft coupling

- Compact shaft coupling

- Engine shaft coupling

- Hydraulic brake

- Safety brake

- Pump shaft coupling

- Industrial shaft coupling

- Drive system

- Disc clutch

- Machines coupling

- ATEX coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.