- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

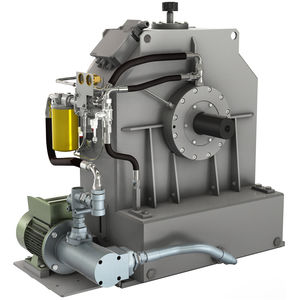

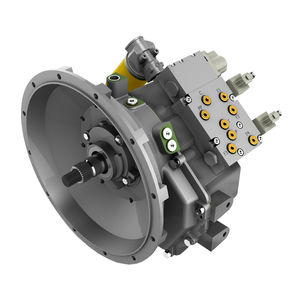

Hydrodynamic coupling KX pumpmotormachines

Add to favorites

Compare this product

Characteristics

- Type

- hydrodynamic

- Product applications

- pump, motor, machines, valves

- Construction

- double, large

- Other characteristics

- torque

- Installation system

- flange

- Rotational speed

Max.: 1,800 rpm

(11,309.73 rad.min-1)Min.: 1,000 rpm

(6,283.19 rad.min-1)

Description

HYDRAULIC COUPLING FOR ELECTRIC ENGINES – STARTER

The KX is a constant fill fluid coupling with a special patented circuit designed to start up large inertia machines driven by electric motors. The circuit includes two internal tanks connected by a scoop. The scoop works like a differential pump transferring the fluid from one chamber to the other and finally into the coupling working circuit through external adjustable valves. This double passage allows a long starting time with very low starting torque and absorbed current by the electric motor, virtually isolating the inertia of the driven machine.

The coupling can work using both oil and treated water as standard.

KX SERIES HYDRAULIC COUPLING: OPERATING CONDITIONS

The fluid quantity in the working circuit is less than in traditional constant fill fluid couplings, as the fluid level is much lower than the rotating axis. The reduced fluid quantity in the working circuit allows low starting torque. During input rotation the scoop transfers the fluid from tank A to tank B and then, through an adjustable valve for starting time regulation, to the working circuit.

Catalogs

KX FLUID COUPLINGS KX SERIES

4 Pages

B3M-BM-BMS FLEXIBLE COUPLINGS

12 Pages

Related Searches

- Flexible shaft coupling

- Shafts coupling

- Friction brake

- Flange shaft coupling

- Torque shaft coupling

- Spring brake

- Disc brake

- Transmission shaft coupling

- Friction clutch

- Sleeve shaft coupling

- Compact shaft coupling

- Engine shaft coupling

- Hydraulic brake

- Safety brake

- Pump shaft coupling

- Industrial shaft coupling

- Drive system

- Disc clutch

- Machines coupling

- ATEX coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.