Software for the automotive industry FORGE®analysissimulationdesign

Add to favorites

Compare this product

Characteristics

- Function

- analysis, simulation, design, optimization, tracking, balancing

- Applications

- process, industrial, flow, mechanical, for the automotive industry, for the aerospace industry, for medical applications, for shaft

Description

FORGE® is the software solution for the simulation of hot and cold forming processes. It has been the flagship product of Transvalor for almost 35 years and is used by customers throughout the world. FORGE® fulfills the needs of companies producing forged parts for a variety of industrial sectors.

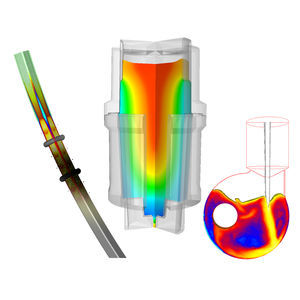

Anticipate the presence of defects

FORGE® software has unique features such as point tracking to easily detect any cold-shut areas in the part and to predict metal fibering which is essential to ensure that forgings possess good mechanical properties. Innovative marking techniques allow to materialize the segregations located in the center of the billet or to identify flow-through defects.

FORGE® incorporates several damage criteria that can be enabled to detect critical areas on the part.

Forging tools and equipment

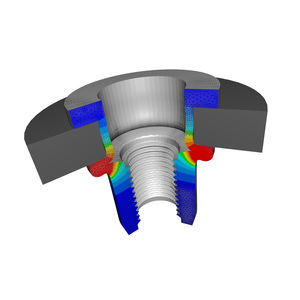

Tool life is a major challenge for which FORGE® predicts stresses, abrasive wear, temperatures and also areas subject to elastic or plastic deformation.

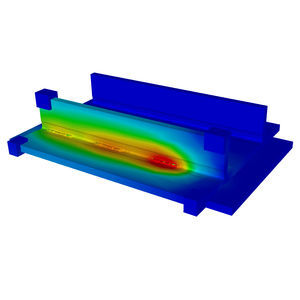

FORGE® predicts forging loads, energies consumed,torques and powers developed during each deformation operation. Then you can anticipate whether the effort required does not exceed the maximum capacity of your equipment, balance forging loads between the different stages and view die balancing and deflection problems.

Optimizing material savings

Transvalor has been the first software provider to promote the concept of automatic optimization applied to material forming processes. Optimizing the starting billets to automatically improve yield or determining the ideal rolled preforms to ensure complete and defect-free die filling.

Catalogs

Related Searches

- Automation software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Development software

- Engineering software

- Optimization software solution

- Planning software

- Safety software

- Tracking software solution

- Flow software

- Construction software

- Mechanical software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.