Plastic injection process software REM3D®simulationdesignquality

Add to favorites

Compare this product

Characteristics

- Function

- simulation, design, quality, packing

- Applications

- plastic injection process, mechanical, chemical

Description

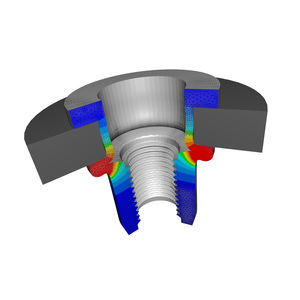

REM3D® is a finite element simulation software dedicated to plastic injection processes and especially for polyurethane foam molding. Optimize your processes to increase your productivity and improve the quality and the in-use properties of your parts.

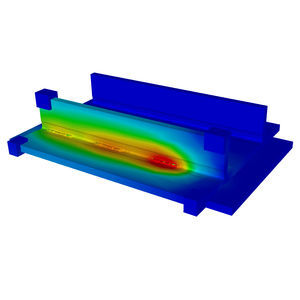

Prediction of final properties for plastic and foamed parts

Based on a local density map, REM3D® provides reliable answers for the prediction of parts resistance as well as insulating, noise and/or comfort properties.

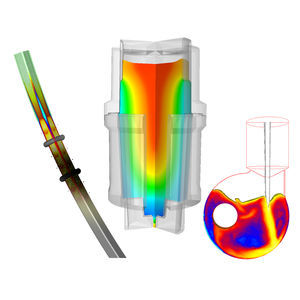

Simulate a ‘dual foam’ pouring and observe the transition zones between foams of different rigidities.

Taking into account "mold tilting" translates realistic process conditions to be as close as possible to reality. The integration of functionalities such as automatic mold tilting or the impact of gravity on the melt flow allows to analyze the real conditions of your processes to guarantee the homogeneity of your parts. The study of the positioning of the injectors limits the presence of defaults.

Thus, you get reliable predictions concerning the resistance of your parts but also the insulating and comfort properties of the foams.

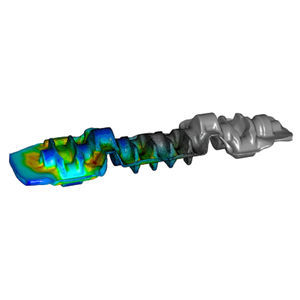

For plastics with fibers, REM3D® determines the fibers orientation during the filling stage and after cooling. You can easily observe the orientation tensor during the injection phase in an ellipsoid form and highlight the orientation from core to skin.

Catalogs

Related Searches

- Automation software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Development software

- Engineering software

- Optimization software solution

- Planning software

- Safety software

- Tracking software solution

- Flow software

- Construction software

- Mechanical software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.