Simulation software THERCAST®developmentqualityengineering

Add to favorites

Compare this product

Characteristics

- Function

- simulation, development, quality, engineering, control, optimization, planning, prototyping

- Applications

- process, construction, for the automotive industry, R&D, for steel construction

- Type

- 3D

Description

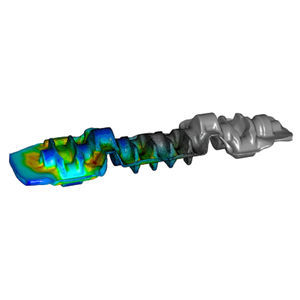

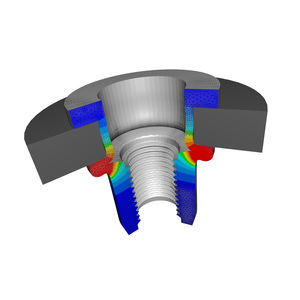

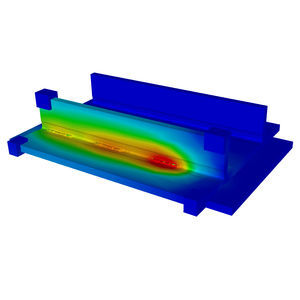

THERCAST® is a 3D finite-element software for foundry processes, continuous casting and ingot casting processes.

The software makes it possible to quickly and accurately analyze your manufacturing process, from the initial casting to the end of solidification. Thus, you anticipate manufacturing defects allowing you to produce high-quality components and reduce the prototyping phase.

A daily partner

In extremely competitive and ever-changing markets, simulation is now an essential step in the development cycle of high-value cast parts.

THERCAST® offers a complete and modular solution which will be able to provide you with valuable support for the production of ingots, castings or even continuous casting.

THERCAST® is your partner at every stage of your activity:

In R&D phase, you can develop innovative or complex processes and optimize them by choosing the best parameters.

In quotation phase, THERCAST® offers the possibility to simulate the production of the desired part in order to position yourself more quickly.

THERCAST® is also defined as time-to-market accelerator thanks to an increased definition of your manufacturing capabilities. You save time in the prototyping phase and control costs in the production phase.

Thanks to a better understanding of physical phenomena, THERCAST® guarantees the feasibility of the part and limits non-quality costs by detecting casting defaults upstream.

THERCAST® also supports you in your engineering choices, in order to meet the needs expressed by your customers but also in a continuous improvement approach by optimizing existing productions.

Catalogs

Related Searches

- Automation software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Development software

- Engineering software

- Optimization software solution

- Planning software

- Safety software

- Tracking software solution

- Flow software

- Construction software

- Mechanical software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.