Simulation software DIGIMU®developmentindustrialfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Function

- simulation, development

- Applications

- industrial, for the aerospace industry, for steel construction

Description

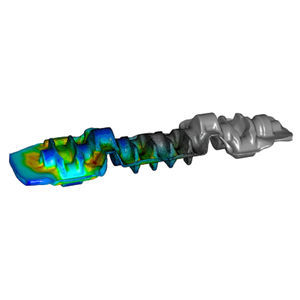

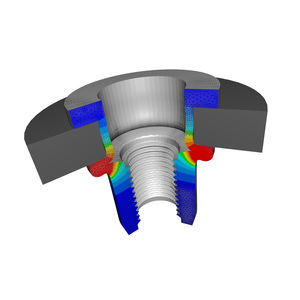

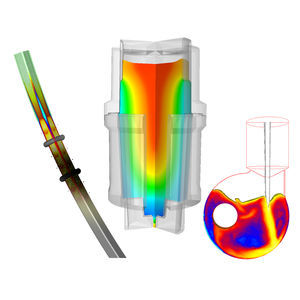

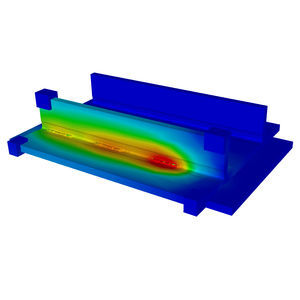

The aim of DIGIMU® is to propose an industrial solution for simulating microstructure changes, at the mesoscopic scale and on Representative Elementary Volumes (REVs), during metal forming processes.

Software derived from Research

DIGIMU® is the result of research projects conducted for more than ten years at the CEMEF (Material Forming Center) in collaboration with many industrial stakeholders from the metallurgy, aeronautics and nuclear sectors. The two pillars of DIGIMU® software development are the extensive experimental work and the constant improvement of existing numerical methods, which allow CEMEF to be at the forefront of world research in the field.

The full-field approach

The full-field approach proposed by DIGIMU® has two main objectives:

To simulate local and heterogeneous phenomena that are undetectable to larger order models

To improve medium-field models used for industrial part-scale simulations

DIGIMU® generates digital polycrystalline microstructures representative of the material's heterogeneities (compliance with the topological characteristics of the microstructure). The boundary conditions applied to the REV are representative of that experienced by a material point at the macroscopic scale (thermomechanical cycle of the considered point). Based on a Finite Elements formulation, the various physical phenomena involved during metal forming processes are simulated (recrystallization, grain growth, Zener pinning due to second phase particles, etc.).

Catalogs

DIGIMU 3.0

2 Pages

Related Searches

- Automation software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Development software

- Engineering software

- Optimization software solution

- Planning software

- Safety software

- Tracking software solution

- Flow software

- Construction software

- Mechanical software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.