Software for welding applications TRANSWELD®analysisinterfacesimulation

Add to favorites

Compare this product

Characteristics

- Function

- analysis, interface, simulation, safety, prototyping

- Applications

- process, industrial, construction, for the automotive industry, R&D, for welding applications

Description

TRANSWELD® offers an industrial solution for predicting the thermomechanical behavior of an assembly during a welding process.

A 100% predictive numerical tool

In markets where the safety of welded assemblies is essential, analysis with TRANSWELD® offers a global and innovative solution to anticipate welding defects.

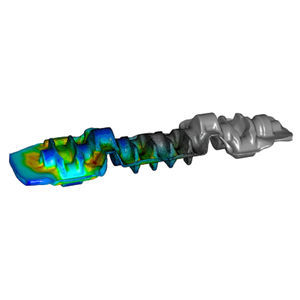

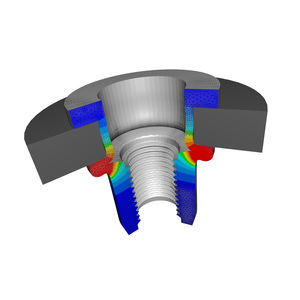

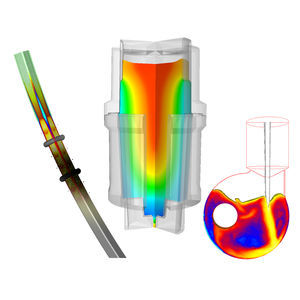

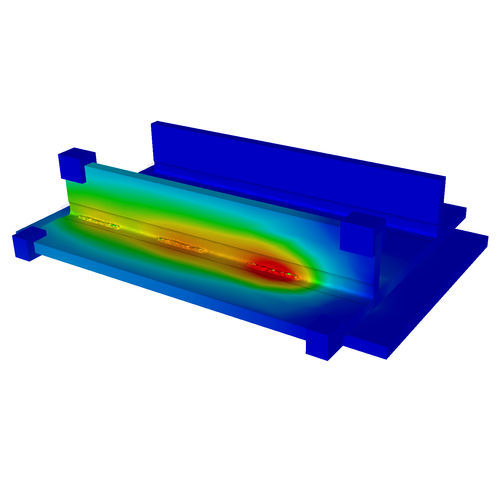

Our simulation software integrates multi-physical models to simulate the real behavior of the metal in the liquid/mushy state to perform a complete analysis of the material evolution.

TRANSWELD® also makes it possible to study the microstructure of the solid state assembly. Then, you ensure the conformity of your welded part without going through the prototyping stage.

Our software is 100% predictive. It allows you to observe your welding processes numerically by applying real conditions. For example, you can visualize the heat source movement during the simulation of laser welding or arc welding.

TRANSWELD® benefits from all the research and implementations available in other Transvalor suite software.

This allows you to prototype your entire product: from the manufacturing of your parts (forged or cast) to the final assembly by welding.

Catalogs

TRANSWELD 1.0

2 Pages

Related Searches

- Automation software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Development software

- Engineering software

- Optimization software solution

- Planning software

- Safety software

- Tracking software solution

- Flow software

- Construction software

- Mechanical software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.