Analysis software solution COLDFORM® developmentsimulationdesign

Add to favorites

Compare this product

Characteristics

- Function

- analysis, development, simulation, design, prototyping

- Applications

- for medical applications, for watchmaking, R&D

Description

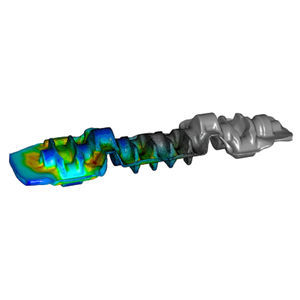

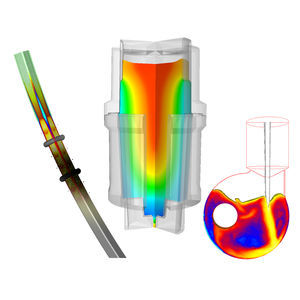

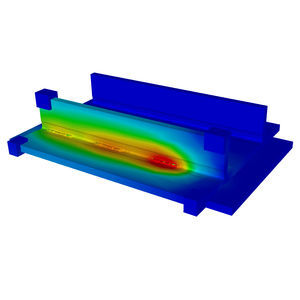

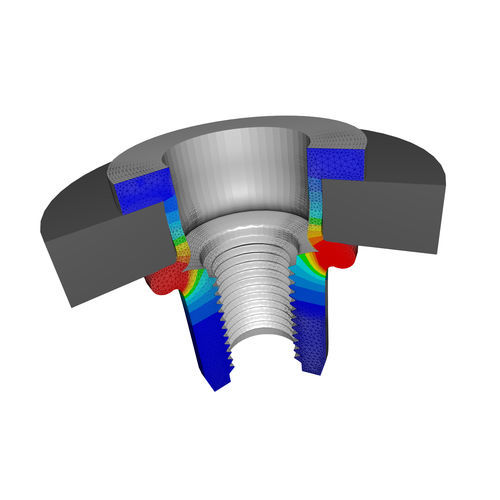

COLDFORM® is a finite element analysis software dedicated to the simulation of cold forming processes. Its advanced functionalities cover a very wide range of applications including cold heading for fasteners, cold rolling and sheet metal forming. Thus, the parts simulated are found in multiple sectors: fastening solutions, aerospace, automotive, medical, fine watchmaking.

Conception and optimisation of cold forming processes

The benefits of COLDFORM® can be observed at all steps in your activity:

During the R&D phase, for the development of innovative or complexe products :

lifting technological barriers to innovation

reducing design costs

reducing development costs

making products more reliable and reducing technical risks

building your company’s knowledge and expertise

During the production phase, to optimize the various forging steps and improve manufacturing processes :

reducing costs related to prototyping and workshop testing

reducing the quantities of materials used

optimizing the manufacturing processes

extending die service life

During the negotiation phase, thanks to the control of production costs and improved schedule reliability:

considerably shortening the design phase

reducing material costs

reducing time-to-market

controling risk provisions

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.