- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

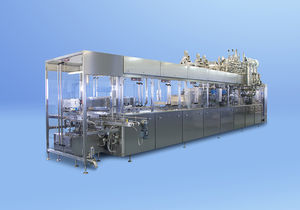

Horizontal cartoner 22S, 412S seriesautomaticsemi-automatic

Add to favorites

Compare this product

Characteristics

- Type

- horizontal

- Other characteristics

- automatic, semi-automatic

- Throughput

Max.: 100 p/min

Min.: 20 p/min

Description

Trepko developed three machinery solutions that suit various production requirements. These machines can cater for production requirements of between 20 and 100 packs per min.

1. Semi automatic 22S sealing machine tailor made to suit smaller production requirements. This machine requires an operative to load and remove the sandwich skillets before & after the sealing process. Quick release assemblies are utilised to allow for swift changeover times.

2. The newly developed 412S and 422S twin lane machine is fully automatic and will dispense, erect and finally seal the cardboard skillets at an output speed of 60 packs per minute. Size change is simple with quick release assemblies allowing for swift changeover times fir the various width skillets available.

This machine is also offered in a dual index fomat which has an increased output speed of 100 packs per minute inline with fully automatic sandwich product equipment.

Catalogs

Related Searches

- Packing machine

- Automatic filler

- Automatic packing machine

- Liquid filler

- Filler for the food industry

- Packing machine for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Volumetric filler

- Semi-automatic filler

- Film packing machine

- Filling system for the chemical industry

- Multi-head filler

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Automatic palletizer

- Case packer

- Packaging machine for the food industry

- Layer palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.