- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

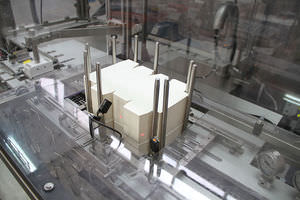

Wrap-around case packer 710 seriesautomatic

Add to favorites

Compare this product

Characteristics

- Type

- wrap-around

- Operating mode

- automatic

- Unit throughput

20 p/min

Description

TREPKO wrap-around packers are fully automatic machines which group and pack products in cases or trays formed from a flat sheet of corrugated board. The flat sheet, referred to as a ‘blank’, is folded and glued around the pre-arranged products to form the case/tray. The machine consists of flexible basic modules designed to meet the current customer requirements regarding pack types and sizes and also allows for future additions if and when they are required.

The machine design incorporates unique and interchangeable ‘blank’ feeders to allow different case/tray sizes to run on the same machine. This changeover procedure requires little time with all the different sized change parts easily and quickly accessible.

All packing takes place on one level with a maximum output speed of 20 cases per minute. The machine can also be loaded with several ‘blank' stacks for longer runs without the need for loading.

• versatility: variety of packaged products in various shapes and sizes, possibility of using different patterns in the box, possibility of using different boxes on the same machine, quick and easy changeover for a different size or shape of the box, possibility of future additions

• reliability: modern material and high quality construction contributes to easy and cheap maintenance and guarantees the machine’s long life, modern drive systems provide high standard of packaging and reliability of the machine

• accuracy: perfectly formed and filled box during packaging process

• ergonomic: easy operation and maintenance

Maxmum output: 20 box/min.

Box dimension: min. 200x105x70

max. 600x240x350

Power: 17 kVa

Control/Pilot system: 24 V

Machine weight: 1300 kg

VIDEO

Catalogs

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Filler for the food industry

- Packing machine for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Volumetric filler

- Semi-automatic filler

- Film packing machine

- Multi-head filler

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Automatic palletizer

- Case packer

- Packaging machine for the food industry

- Layer palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.