- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

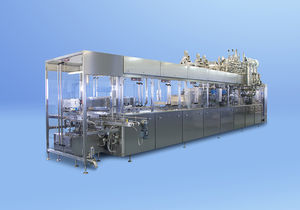

Cup filling and sealing machine 200 Seriesautomaticliquidsfor pasty products

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Container type

- cup

- Fill product

- liquids, for pasty products, for dairy products

- Product applications

- cheese, for butter, sauce

Description

Trepko’s 200 Series provides flexible and effective solutions for the filling and closing of pre-formed containers. The machinery within this range achieves outputs of up to 14,000 cups/hour. Four machine sizes are available (210-220-230-240) dependent on the required output, container size and options required, each with different frame sizes and number of lanes.

Thanks to their flexibility the 200 Series machines meets small, medium and high production needs especially limited by production space. The compact construction of this machinery allows for efficient use of the floor-space at the user’s production facilities.

The machine complies with the strictest hygiene requirements within the food industry. The packaging hygiene can be enhanced by a number of optional features such as CIP/SIP facility for the filing systems and sterile air cabins etc. For large frame sizes, cup sterilization options are also available.

Ever mindful of a quick market changes the 200 Series flexibility guarantees that new packaging ideas can be accommodated. The 200 Series represents full production flexibility in terms of product and containers changes. Extra product depositors can be installed as a pre or post-filling of semi-liquid or dry products. Utilising the cassette concept allows fast changeover between alternative container sizes.

• individuality: tailor made solutions

• flexibility: available for a variety of cups and containers, a variety of products to be filled (desserts with vertical, horizontal and twisted layers, layered dessert with icing, filling cream in an attractive pattern)

VIDEO

Catalogs

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Filler for the food industry

- Packing machine for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Volumetric filler

- Semi-automatic filler

- Film packing machine

- Multi-head filler

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Automatic palletizer

- Case packer

- Packaging machine for the food industry

- Layer palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.