- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

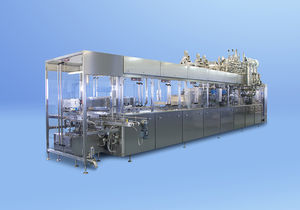

Automatic filling machine 500 seriescupfor pre-formed containersfor food

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- cup, for pre-formed containers

- Product applications

- for food, for liquids, for semi-liquids

- Domain

- for the food industry, for the cosmetics industry, for the chemical industry, for the pharmaceutical industry

- Type

- rotary

- Other characteristics

- high-speed

- Throughput

2,500 p/h, 5,000 p/h

Description

The TREPKO 500 Series is designed around a carousel principle for handling pre-formed containers and provides a medium to high speed production output.

The flexible nature of the 500 Series allows for a variable machine length to suit the specified product. This allows a choice of several multi-fill applications with additional depositors for liquid, semi-liquid, dry products or simple hand placement areas. The 500 Series is ideal not only for filling but also for creating sophisticated multi-layer products, especially desserts.

• flexibility: several multi-fill applications with additional depositors for liquid, semi-liquid, dry products or simple hand placement areas, available for a variety of cups and containers

• individuality: automation of the packaging process, safe and easy operation, modern drives, mechanical and modern servo technology drives ensures a smooth and reliable operation, low maintenance costs and long life-time

• length of the machine to suit the specified product, quick and easy changeover between different packaging sizes

• reliability: modern material and high quality construction contributes to easy and cheap maintenance and guarantees the machine’s long life

Hygienic

Sterile air cabin

Chemical sterilisation of cups/foils

UV radiation of cups/foils

CIP/SIP of the dosing system

CIP/SIP of the packaging area

Gas flush

Efficiency

• Stack feeding magazine for cups/lids

• Foil sledge

• Automatic volume adjustment

Closing

• Pre cut foil heat seal

• Snap-on-lid

• Foil from reel

Other

• Pre or post-depositors

• Dry product fillers

• Compensator

• Date marking

• Modem

Catalogs

500 series

4 Pages

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Filler for the food industry

- Packing machine for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Volumetric filler

- Semi-automatic filler

- Film packing machine

- Multi-head filler

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Automatic palletizer

- Case packer

- Packaging machine for the food industry

- Layer palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.