- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

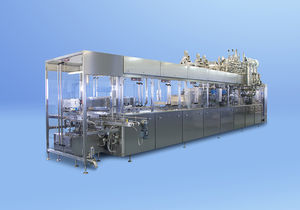

Automatic filling and sealing machine 400 Seriescupfor pre-formed containersliquids

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Container type

- cup, for pre-formed containers

- Fill product

- liquids, for pasty products, for dairy products

- Product applications

- for the food industry

Description

The TREPKO 400 series is a range of servo driven flexible container handling systems which can carry out a wide variety of filling and sealing applications.

These machines are designed to handle numerous types of packaging including troublesome parallel sided containers. Recent developments in this series include applications to seal cardboard sandwich packaging, plastic alcoholic beverages and high speed filling lines for the salad industry.

All TREPKO servo conveyors are designed to minimise the number of change parts required between packaging changeovers and therefore maximising production and output. To achieve long term flexibility, on the whole lines are built in a modular format enabling additional assemblies to be added subject to customer requirements.

Trepko servo machines are constructed out stainless steel, this is combined with modern drive systems for a smooth and reliable operation.

• a wide variety of filling and sealing applications

• modular format

• minimal number of change parts required between packaging changeovers

• the machine construction allows for the addition of equipment as and when required

• modern dosing system

• machines are designed for individual needs

• available a different size and shape of containers

Number of filler points: Dependent on customer requirements

Number of lanes: Dependent on customer requirements. Standard range comprises of 1,2,3,4,6,8 and 10 lanes, single or double index

Maxmum output (cups/h): Dependent on number of lanes and product being filled

Max. cup dimensions (mm): Up to 200 mm dia

Min./Max. cup height (mm): Up to 130 mm

VIDEO

Catalogs

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Filler for the food industry

- Packing machine for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Volumetric filler

- Semi-automatic filler

- Film packing machine

- Multi-head filler

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Automatic palletizer

- Case packer

- Packaging machine for the food industry

- Layer palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.