- Products

- Catalogs

- News & Trends

- Exhibitions

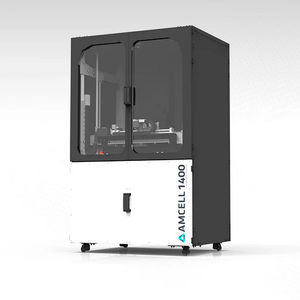

Metal additive manufacturing machine AMCELL 8300®plasticindustriallarge-format

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- metal, plastic

- Applications

- industrial

- Other characteristics

- large-format

- X travel

300 mm

(11.81 in)- Y travel

300 mm

(11.81 in)- Z travel

350 mm

(13.78 in)- Weight

1,300 kg

(2,866.01 lb)

Description

The first and only platform in the market able to mass-produce 3D Printed parts in metals and polymers.

Mass production Cost-Effective in metal and polymers

Automated Additive Manufacturing Solutions

AMCELL 8300® makes additive manufacturing a viable solution for high-volume manufacturing. An automated Industrial 3D Printer for 24/7 production of functional parts

Accurate and functional parts

• - Polymers

• - Composites

• - Metals

• - High tolerance (ISO 2768)

• - Mass production

EVAM Software®

• - Centralized control and monitoring

• - Feedstock smart control

• - Production optimization

• - Printer integration

• - Build simulation

• - Scheduling

• - Shopfloor connectivity

• - Quality and process monitoring

• - Traceability

Intelligent automatic system

Enables 24/7 functional final parts production.

How it works

Highest throughput of final parts and automated!

AMCELL 8300 is an automated additive manufacturing cell for the mass production of high complexity and precise final parts, controlled by EVAM Software to manage production orders, in-process control, and reduce machine downtimes.

Manufacturing orders, process monitoring, feedstock control, smart environmental control, are just some of the features that make AMCELL 8300® a real platform for mass production.

Software-controlled workflow and process monitoring

AMCELL 8300® includes EVAM Software®, the most advanced production control and remote monitoring solution.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.