- Products

- Profile assembly bolt connector

- trimat srl

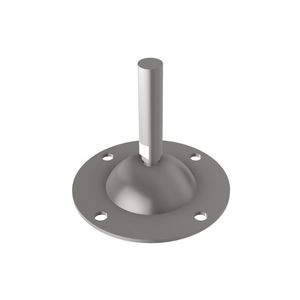

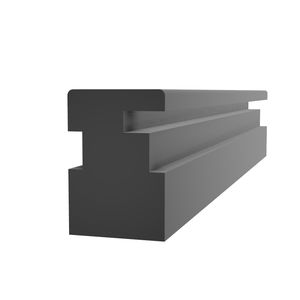

Profile assembly bolt connector F3030

Add to favorites

Compare this product

Characteristics

- Options

- for profile assembly

Description

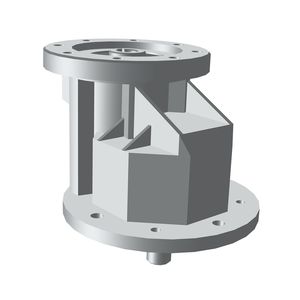

Assembling two modular aluminum profiles requires little time for processing, a limited number of tools and a familiarity that is acquired in a very short time. The nuts and bolts required by the construction system with extruded profiles are reduced to a few codes that allow modifications to be made to existing structures at any time, even on site. A service hole, a lowered cylindrical head screw, an Allen key and a rolling tap are the only necessary actors; ingenuity, imagination and the daily needs of setting up load-bearing structures or protective barriers are the driving force; the screws, special nuts and dedicated accessories are the glue of the entire modular construction system of extruded aluminum profiles.

for lowered slot profiles

allows the coupling of the profiles without drilling the service hole

it does not occupy the lateral grooves of the profiles allowing the insertion of panels without notches

Catalogs

02-BOLTS-TOOLS

24 Pages

EN-ALUMINUM-STRUCTURAL-PROFILES

228 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.