Belt conveyor 531071horizontalstraightfood

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Form

- horizontal, straight

- Transported product

- food, for packaging

Description

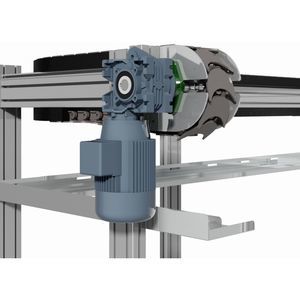

TRIMAT builds, according to the project and / or in accordance with the indications provided by the customer, idle, motorized roller conveyors and conveyor belts. Each manufacturing plant needs to move objects, to load or unload an automatic machine, to perform the functions of enslavement and evacuation without the obligation of the presence of man, both to obviate the alienating repetitiveness of the operations, and to alleviate the fatigue of the operator, both to guarantee continuity to the production process which, in the absence of interruptions physiologically linked to the human being, becomes more profitable. The conveyor, the idle roller conveyor, the motorized roller conveyor, the interlocking conveyor, the evacuator belt often have low cost and high functionality, a high cost benefit ratio. We meet a conveyor belt every day: at the airport, at the supermarket, in the gym: the conveyor belts and roller conveyors are simple machines that streamline the logistics of the factory, they are the natural completion of an automatic machine, they allow man to concentrate on the realization of the piece and on the management of the equipment instead of making it porter of the plant.

Intended for packaging in the fruit and vegetable world, the conveyor belt system is synchronized with the cycle time of the upstream and downstream plants and performs the function of temporary stock. Managed belts are made of PVC compatible with FDA regulations.

Catalogs

EN_PROJECTS

60 Pages

Related Searches

- Rail conveyor

- Belt conveyor

- Conveying belt

- Roller rail conveyor

- Plastic conveyor belt

- Perforated conveyor belt

- Drag chain conveyor

- Food conveyor

- Stainless steel conveyor

- Modular conveyor belt

- Discharge conveyor

- Curved rail conveyor

- Loading conveyor

- Part conveyor

- Straight conveyor

- Inclined conveyor

- Metal conveyor belt

- Gravity conveyor

- Air conveyor

- Packaging conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.