Centering measuring instrument OptiCentric® UltraPrecisionopticalopto-mechanicaloptical lens

Add to favorites

Compare this product

Characteristics

- Measured value

- centering

- Technology

- optical, opto-mechanical

- Applications

- optical lens

- Other characteristics

- high-precision

Description

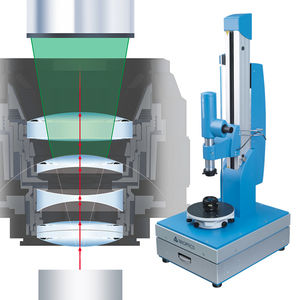

Die OptiCentric® UltraPrecision devices transfer the advantages of the OptiCentric® 100 series to the measurement of large, heavy lens assemblies with a weight of up to 1200 kg and a diameter of 800 mm.

The system‘s design on a granite base provides you with extraordinary rigidity and thermal stability, so that the greatest accuracy is achieved even with slowly curing adhesives.

Key Features

Measuring extremely large, heavy lenses with up to 1200 kg weight, max. Ø 800mm, max. height 1500 mm

Granite based construction provides exceptional rigidity and thermal stability

Linear air bearing with encoder for precise positioning of the upper measurement head

Ultra-accurate measurement of lens centering with autocollimation measurement head

Exchangeable head lenses for virtually unlimited measurement range without the need for inconveniently long stage movements of the measuring head

Measurement in reflection or transmission

Large range of software options: MultiLens, AspheroCheck, SmartAlign

Optional center thickness measurement with an accuracy of up to 0.15 µm

Second measurement stage below the sample for extended measurement capabilities

Fully integrated accessories like tool stage, measuring gauge, glue dispenser, UV illumination

Advanced software controls the complete OptiCentric® system

Applications

For large heavy optics in microlithography, space and other industries

Measurement centering of optical system with MultiLens Software module

Measuring the optical axis with respect to a mechanical axis (e.g. housing axis)

Measurement of EFL, BFL, FFL, MTF on axis (OptiSpheric® upgrade)

Catalogs

OptiCentric® UltraPrecision

8 Pages

Other TRIOPTICS products

Systems for Optical Centration Measurement and Alignment

Related Searches

- Measuring device

- Test stand

- Thickness measuring machine

- Benchtop measuring device

- High-precision measuring device

- USB measuring device

- Surface measuring machine

- Industrial profiler

- Optical measuring device

- Process measuring device

- Stationary thickness measuring machine

- Automatic calibration thickness gauge

- Non-contact measuring device

- Diameter gauge

- Goniometer

- Thickness measuring device

- 3D measuring device

- Shape measurement profiler

- Infrared measuring instrument

- Motorized goniometer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.