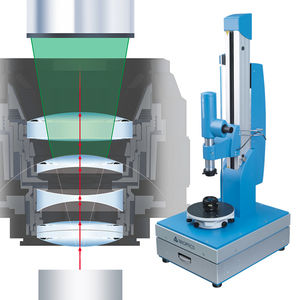

Alignment measuring instrument OptiCentric® UltraPrecision Bondingoptical lensprocesssemi-automatic

Add to favorites

Compare this product

Characteristics

- Measured value

- alignment

- Applications

- optical lens, process

- Other characteristics

- semi-automatic

Description

Semi-automated bonding is the optimum choice for higher volume production tasks.

OptiCentric® UltraPrecision is upgraded for semi-automatic bonding with a frame containing all bonding and measurement equipment. All tools are fully integrated and software-controlled for an efficient lens alignment and bonding process.

Key Features

Alignment accuracy better than 2 µm

SmartAlign Software for the precise alignment in non-centered housings

All bonding and measurement tools are integrated on a motorized frame

Automated and precise height adjustment of the bonding frame for stepwise assembly of optics up to 1.5m height

Highly efficient process because time consuming exchange of alignment and bonding devices is not needed

Based on OptiCentric® UltraPrecision for the measurement of large and heavy lenses

Manual coarse positioning of the alignment tools, automatic and precise alignment of the lens in the cell

Alignment of the optics with three linear actuators in one step

Advanced software controls the complete OptiCentric® Bonding System including measurement, SmartAlign calculations, alignment, glue bonding and UV curing

Contactless measurement of lens and housing parameters

Applications

Characterization of a complete lens assembly

Assembly of large and heavy lenses for micro lithography, space or other industries

Assembly of IR optics

VIDEO

Catalogs

No catalogs are available for this product.

See all of TRIOPTICS‘s catalogsOther TRIOPTICS products

Systems for Optical Centration Measurement and Alignment

Related Searches

- Measuring device

- Test stand

- Thickness measuring machine

- Benchtop measuring device

- High-precision measuring device

- USB measuring device

- Surface measuring machine

- Industrial profiler

- Optical measuring device

- Process measuring device

- Stationary thickness measuring machine

- Automatic calibration thickness gauge

- Non-contact measuring device

- Diameter gauge

- Goniometer

- Thickness measuring device

- 3D measuring device

- Shape measurement profiler

- Infrared measuring instrument

- Motorized goniometer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.