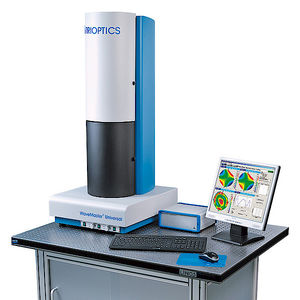

Automated interferometer WaveMaster® PRO 2 / PRO 2wavefront division

Add to favorites

Compare this product

Characteristics

- Options

- automated, wavefront division

Description

The quality and efficiency requirements placed on the mass production of small plastic or glass lenses, optical windows are continually rising. The use of wavefront measurement technology in mass production can yield a great deal of optimization potential.

WaveMaster® PRO 2 & PRO 2 Wafer set new standards in the series testing of optics and optical wafers. With a typical measurement time of 2 sec. per optic and a fast tray or wafer change, the prerequisites are met for use in mass production. With respect to measurement technology, WaveMaster® PRO 2 & PRO 2 Wafer determine with a Shack-Hartmann sensor the wavefront from which various parameters are derived. A comparison to the design data is then performed per lens. A very good data pool for additional optimizations in production.

Key Features

Measurement duration: less than 2 seconds per lens

Full automatic measurement of large amounts of samples (wafer or preloaded trays)

User selectable PASS and FAIL criteria

Absolute or relative wavefront measurement

Complete Wavefront analysis (PV, RMS, Zernike, PSF, MTF, Strehl)

Available in two setups

Setup for the measurement of spherical and aspherical lenses (single lenses or wafer)

Setup for the measurement of flat surfaces (single surface or wafer)

Export of all measurement results for each single lens

Option: Integrated measurement system for the measurement of wafer orientation, overall wafer bow and tilt

VIDEO

Catalogs

No catalogs are available for this product.

See all of TRIOPTICS‘s catalogsRelated Searches

- Measuring device

- Benchtop measuring device

- High-precision measuring device

- USB measuring device

- Optical measuring device

- Process measuring device

- Interferometer

- Non-contact measuring device

- Diameter gauge

- Thickness measuring device

- 3D measuring device

- Autocollimator

- Electronic autocollimator

- Infrared measuring instrument

- Wavefront sensor

- Optical lens measuring instrument

- Automated interferometer

- Alignment measuring device

- Semi-automatic measuring instrument

- Opto-mechanical measuring instrument

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.