- Machine-tools

- Machining Center

- 4-axis machining center

- TRONZADORAS MG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

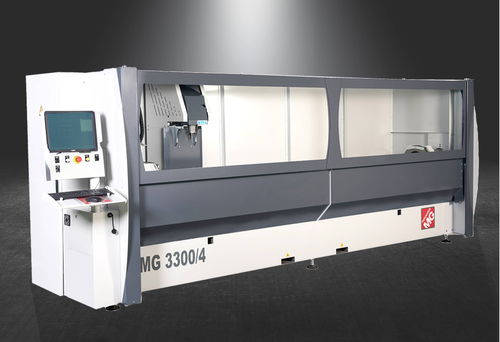

4-axis CNC machining center MG-3300 /4verticalcolumn typefor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- vertical

- Structure

- column type

- Machined material

- for aluminum, for plastics

- Associated functions

- milling

- Other characteristics

- high-speed, high-precision, high-performance, high-productivity

- X travel

3,300 mm

(129.92 in)- Y travel

250 mm

(9.84 in)- Z travel

200 mm

(7.87 in)- Rotational speed

Max.: 20,000 rpm

(125,664 rad.min-1)Min.: 2,000 rpm

(12,566 rad.min-1)- Power

5.5 kW

(7.48 hp)

Description

Machining center with moving column and vertical spindle with 4 axis controlled by CNC including rotation of the clamp base which allows any angle ranging from -90 ° to + 90 ° in automatic working cycle.

-Motor HITECO of 5,5KW standard

-Quick change hand tool cone ISO30 pneumatically controlled;

-Automatic tool change with station for 4 tools (optionally 8 tools)

-4 pneumatic standard vices with manual positioning ( -Automatic positioning and more vices as option)

-Possibility to work aluminum, PVC, steel up to 4 mm and -stainless steel up to 3 mm with a specific accessory.

Axis movement and clamps rails with recirculating ballscrew and servodrive

Motion rotated clamp base by rail and wheels

Numerically controlled axes with 4 brushless motors

Transmission axis with tilted teeth rack and pinion

Start cycle with two-handed safety device

4 horizontal pneumatic clamps with low pressure device

Mist lubrification (emulsified oil)

Tool magazine cones ISO30

Vice jaws PVC adjustable using keys

Spindle motor driven by inverter

Swiveling console

USB 2.0 port on the control panel and ethernet RJ45 socket

Preinstalled barcode reader connection

NC - Industrial PC with Intel microprocessor

LCD display - TFT (800 x 600) color 10.4 "- touch screen

Operating system Windows XP Embedded RT

Software- 3D dimensional

Indication vice positioning software with reference line of metric

VIDEO

Catalogs

No catalogs are available for this product.

See all of TRONZADORAS MG‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- High-precision CNC machining center

- Drill

- High-performance CNC machining center

- Milling CNC machining center

- Electric drill

- High-productivity CNC machining center

- Column type CNC machining center

- Aluminum CNC machining center

- 4-axis CNC machining center

- Bench-top drill

- Drill press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.