The new TJN jet nozzle offers improved acoustic characteristics and is also more energy-efficient

Nominal sizes: 160, 200, 250, 315 and 400 mm

Visible parts made of high-grade polymer in white aluminium or pure white

Optimised nozzle contours

Discharge angle indication, discharge angle limiting and setting -30 – +30 on a concealed scale

Easy-to-remove face cover ring with bayonet fixing

5 nominal sizes, each with a circular spigot or, as an option, with a connection piece for circular or rectangular ducts

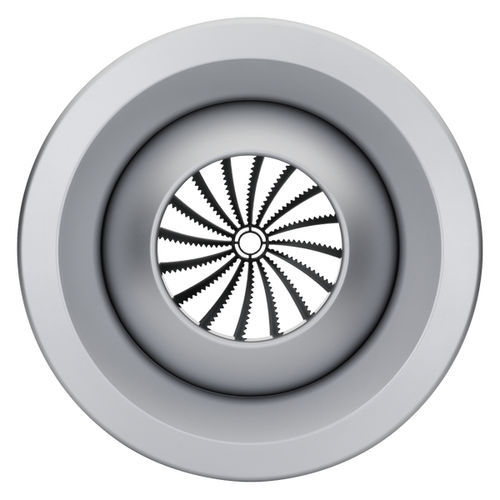

Swirl unit with acoustically optimised air control blades with unique saw tooth edges and cap for two-step reduction of the throw distance

External electric actuator of compact height

Electric actuator allows for integration with the central BMS

Internal thermal actuator with shape memory alloy for the self-powered adjustment of the discharge angle

All variants also available with outer casing

Jet nozzles are the preferred solution wherever the supply air has to travel large distances from the point of discharge to the occupied zone. It is possible to adapt the discharge angle, and consequently the direction of the airflow, to heating or cooling mode. The supply air to room air temperature difference can be -12 - +20 K.

Cooling mode is possible with a positive discharge angle of up to 30°. The supply air jet is directed towards the ceiling, but the higher density of cold air results in an increasing deflection of the air jet towards the floor as the distance from the jet nozzle increases. When the supply air jet reaches the occupied zone, both the supply air to room air temperature difference and the airflow velocity have been reduced to comfortable levels.