- Machine-tools

- Cutting Tool

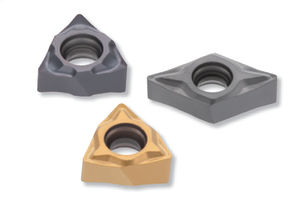

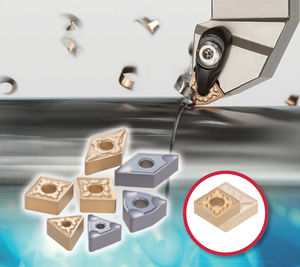

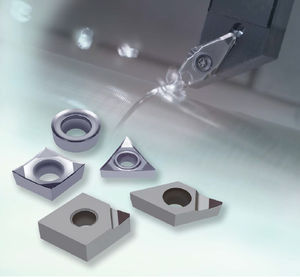

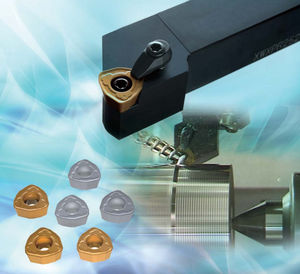

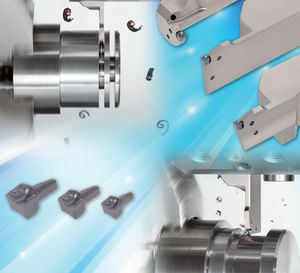

- PCD turning insert

- Tungaloy Germany

PCD turning insert 1QP seriespolycrystalline diamondfor aluminum alloyshigh-speed

Add to favorites

Compare this product

Characteristics

- Material

- PCD, polycrystalline diamond

- Treated material

- for aluminum alloys

- Other characteristics

- high-speed

Description

Tungaloy has added 0.1 and 0.2 millimeter nose radii to its polycrystalline diamond (PCD) tipped turning insert line with NS chipbreaker, increasing the insert size selections.

For years, high-speed aluminum machining with PCD inserts presented significant advantages, but a chip control challenge persisted – until now. Introducing Tungaloy’s cutting-edge ablating technology, which has enabled the development of our sophisticated NS chipbreaker geometry directly on the PCD tip surface. With a specialized rake face and chip redirector designed for 0.1 and 0.2 millimeter nose radii, the NS chipbreaker guarantees reliable and consistent chip forming and evacuation in all aluminum alloy part machining that spans from finishing to light-roughing operations.

A total of fifteen new 0.1 and 0.2 millimeter nose radius PCD inserts have been added with NS chipbreaker. All new inserts are in Grade DX110. Extremely wear resistant, this submicron grain sized PCD grade provides the insert with a strong edge security that promotes superior surface finishing quality and process stability. These new inserts are designed to eliminate birdnesting of chips in machining applications with small corners, shoulder fillets, or undercuts requiring 0.2mm or smaller radii. They are also ideal for finishing applications requiring a close tolerance and high surface quality after a light depth-of-cut pass, in which excellent chip breaking and control are vital. Typical part samples include precision aluminum parts for automotive, optical equipment and instruments, and artificial intelligence robotic system industries.

Catalogs

No catalogs are available for this product.

See all of Tungaloy Germany‘s catalogsRelated Searches

- Milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Indexable cutting insert

- General purpose drill bit

- Hemispherical milling cutter

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

- Shell-end milling tool

- Indexable insert milling tool

- Shoulder milling tool

- 2-flute milling tool

- Twist drilling tool

- Cutting edge milling tool

- Turning indexable cutting insert

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.