- Food industry

- Dairy processing

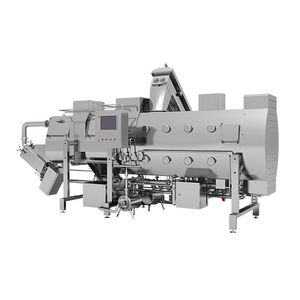

- Stainless steel cheese vat

- Turkoz Makina Sanayi ve tic. a.s.

Hard cheese cheese vat semi hard cheesestainless steel

Add to favorites

Compare this product

Characteristics

- Specifications

- hard cheese, semi hard cheese

- Material

- stainless steel

- Capacity

Min.: 500 l

(132.09 gal)Max.: 15,000 l

(3,962.58 gal)

Description

Process tanks can be manufactured in capacities beginning from 500 liters to 15.000 liters. All tanks manufactured in closed-type base. Most important elements are agitating and curd cheese breaking system. Because these elements directly affect system productivity. Agitators and curd cheese breakers work in both ways. (There two breaker systems). One side of each breaking systems is sharpened. So it cuts curd cheese gently without defecting its texture. And other side are made of moving pallets for agitating. Breaker reductors work double direction and at desired speed. Control system in tanks can only temperature check or offers an operation with receipt using PLC, if desired. And automatic water inlet system can be applied to tank. On tanks, a lift is placed at back of tanks to prevent leaving product inside the tank after evacuation of product. Additionaly, special valves are placed on outlet of tanks to ensure a comfort and clean evacuation. Tanks Works pneumatic based.

Catalogs

No catalogs are available for this product.

See all of Turkoz Makina Sanayi ve tic. a.s.‘s catalogsOther Turkoz Makina Sanayi ve tic. a.s. products

Hard-Semihard cheese production systems

Related Searches

- Metal trolley

- Transport trolley

- Shelf trolley

- Truck

- Pasteurizer

- Cheese slicing machine

- Stainless steel trolley

- Stainless steel cooking unit

- Steam cooking unit

- Mechanical cheese cutting machine

- Industrial cooker with mixer

- Dairy product pasteurizer

- Cheese vat

- Batch industrial cooker

- Cheese forming machine

- Cheese cooking unit

- Stainless steel cheese vat

- Compact pasteurizer

- Electric pasteurizer

- Cheese cutting machine with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.