- Production Machines

- Other Manufacturing Equipment

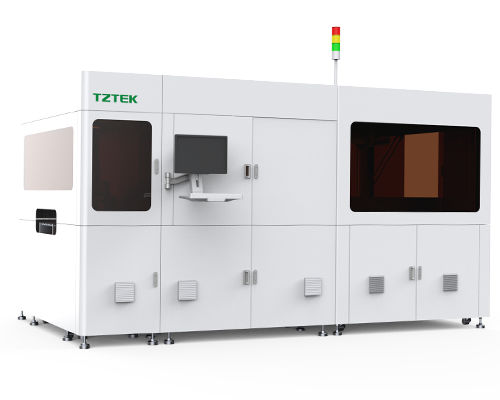

- Optical inspection machine

- TZTEK Technology Co.,ltd

Defect inspection machine opticalindustrialhigh-resolution

Add to favorites

Compare this product

Characteristics

- Technology

- optical

- Sector

- industrial

- Other characteristics

- defect, high-resolution, high-speed, automated

Description

TZTEK glass defect detection equipment is a detection machine developed forglass by applying a number of techniques, such as multiple image defectanalysis, defect detection and classifier algorithm, and precise transmissionmechanism. lt is widely applied to 3C and auto electronics fields for detecting thefront Side, back side and edges of glass in all directions. With features of efficientdetection, intelligent judgment, quick adjustment and multi-level extension, themaximum detection accuray can reach 11 um.

Integrated Working Mode Supporting Modular Detection Extension

• Automatic Ioading/unloading detection mode is easy to operate and manage. the unit consists of a Ioading station, AOI detection station,binning and unloading station, With front end can

support the docking cleaning machine

• Modular design supports Single/double track detection. the detection station could extend more modules according product demand. the unloading station supports 2 bins or more bins

Smarter

• With A1 learning defect features automatically, it could read the QR code online to track data and classify the defects during blank detection

• The detection data can be linked to the QR code and upload system.you can scan the QR code to see the detection resuits

• According to abundan t detection data,after stati stics and an alysis,it could be helpful to improve the production process

More Accurate

• With maximum accuracy up to 11 pm and accurate location of image defects, it is prepared to highly standardized testing requirements

• Reduce product loss in each processing stage and improve yield.escaped rate: <0.5%; Over-kill rate: <10% (can be verified manually)

Other TZTEK Technology Co.,ltd products

Consumer Electronics

Related Searches

- Inspection machine

- Coating machine

- Automatic inspection machine

- Industrial inspection machine

- Defect inspection machine

- Optical inspection machine

- Measurement inspection machine

- Visual inspection machine

- Inspection machine for the electronics industry

- Automated inspection machine

- High-resolution inspection machine

- High-speed inspection machine

- In-line inspection machine

- PCB inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.